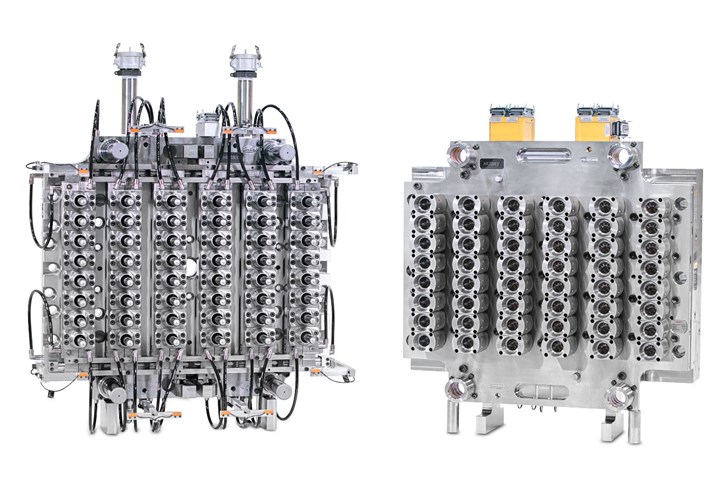

Adaptive PET Preform Mold Meets Fluid Production Requirements

To meet continuously changing consumer demands, Husky highlights the NexPET system which supports a wider variety of applications, more SKUs, shorter production runs and more frequent design changeovers.

Photo Credit: Husky Injection Molding Systems

Husky Injection Molding Systems highlights the launch of its new NexPET system, a mid-volume PET preform molding solution purpose-built to help producers introduce multiple new applications into the market quickly and cost-effectively, a decision taking into account the increasing consumer demand for more personalized products. Further, NexPET is said to deliver an agile, reliable solution to accommodate niche brands or smaller run SKUs.

Husky’s NexPET system reportedly supports a wider variety of applications, more SKUs, shorter production runs and more frequent design changeovers. The system’s flexible design is suited to meet continuously changing production requirements, while maintaining a Six-Sigma part quality. NexPET can run up to a 48-cavity mold and is equipped with a number features, including:

- Up to 25% faster mold changeovers to support a multiple preform design environment.

- Choice of different screw diameters to maximize production output flexibility.

- Reflex PET clamp to distribute the right amount of force and maximizing mold life.

- Rotating end of arm tool with up to three cooling positions to ensure preforms are ejected at ideal temperatures.

- Intuitive, easy-to-use controls that enable fast set-up, maximized uptime, optimal energy management and central control of auxiliaries.

- Adaptive system pressure automatically adjusts oil pressure to suit specific applications while conserving energy.

- Capability to run recycled PET pellets and varying quantity of flakes, supporting sustainability initiatives.

Related Content

-

Training, New Technologies Target Mold Change Optimization

Engel is offering an array of technologies, as well as Basics, Advanced and Expert training courses to help molders optimize their mold-changing process.

-

Design Strategy Tackles Big and Small Complexity Challenges for Southeastern Mold Builder

Delta Mold Inc.’s core values, engineering expertise, five-axis machines and molding capabilities help the team turn a proposal into a manufactured mold or part with custom design, finishing and assembly.

-

LSR Platform Meets Critical Medical Molding Needs

NPE2024: Recent updates to Mastip’s Aquilo platform highlight how its design — from consistent thermal profile to uniform cooling — has made it successful for medical industry projects.