Get the Most from Your Tooling Investment

Alignment, mold protection, tonnage distribution and injection control are the main elements in the molding machine that could affect your tooling investment.

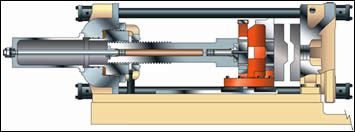

With increasing mold cavitations and functionality, molds can now cost twice as much as the injection molding machines they run in. There are, on average, three molds for every machine. Since molds are typically depreciated over three years, the cost ratio of molds to machines in a given plant is in the range of 10 times! Despite these facts, many molders have a short-term machine investment philosophy and they continue to put brand new molds into machines not capable of handling the weight, speed or precision demanded by today’s molds (see Figure 1).

Would You Put a Formula 1 Engine Into a 10-Year-Old Car?

Why would molders put brand new molds into machines that will underutilize their capability and prematurely wear them out? The primary reason is that the molding industry continues to be an undercapitalized, tight-margin business. In order to get the job, the molder quotes a machine rate for a machine that is just “good enough” for the specific application. Typically, this is a depreciated machine sitting on the molder’s floor or it is a new, low-cost machine that will adequately do the job.

By putting the mold into a marginal machine the molder may compromise the life of the tool, the quality of the moldings and the reliability of the molding cell. When the tool wears prematurely, the moldmaker is blamed for inferior tooling design and is burdened with unfair warranty costs. The molder experiences higher maintenance costs, higher reject rates, lower uptimes and ultimately lower profits than quoted for the job.

The Moldmaker’s Wish

Larger cavitation, multi-level, multi-material and thinner walls—plastic parts are demanding more precision from injection molds than ever before. Moldmakers are producing these large molds with tolerances of 0.0002" (0.005 mm) only to put them in machines with tolerances of 0.005" (0.1 mm) built on decades-old technology. If a moldmaker could design the ideal machine for their mold it would:

- Be perfectly aligned throughout its stroke;

- Sense any part entrapment before applying tonnage;

- Apply tonnage evenly across the mold face; and,

- Inject a precise dose of material simultaneously into each cavity at the optimal pressure.

If this could be done, then mold life would be extended, less maintenance would be required and the system would experience higher uptime.

So what should molders look for in a long-term machine investment strategy to protect their tooling investment and improve their profitability?

Protect Your Investment

Time between major maintenance of a mold can vary widely due to many factors; mold design, resin, processing parameters, care, maintenance, over-clamping, lack of mold protection, poor alignment and poor setup. Some molds last eight to 10 million cycles or more between major maintenance, but the general rule of thumb is around two to three million cycles.

If your mold needs maintenance earlier than this, it will cause the mold to be pulled prematurely from production and require costly rework. If the mold is not producing parts, then it is not paying a return on its investment.

Alignment, mold protection, tonnage distribution and injection control are the main elements in the machine that could affect the tooling investment. The high speed, pressure and temperature environment of injection molding will eventually cause wear in the mold, but this should not be aggravated by the machine’s state of repair or design.

Alignment

With increasing cavitation and the move to stack molding, molds are getting heavier. The machine must be able to support this increased weight without deforming to prevent premature taper and parting line wear. If it cannot, the mold is forced to “align” the machine with its own tapers and other alignment devices on every closing. Since a mold has to accomplish this task sometimes up to 20 times a minute, mold wear and thus poor part quality could occur prematurely.

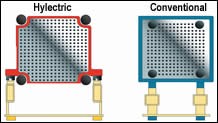

Supporting the platens, and thus the mold, on the solid frame of the machine with linear ways and precision linear bearings instead of the tiebars is one way to greatly improve mold alignment (see Figure 2). By moving support onto the frame of the ma-chine it eliminates relying on the unsupported and flexible tiebars. In addition, the linear bearings provide guidance and alignment of the platens over the full length of the stroke, virtually eliminating tipping and swaying during mold open and close.

Mold Protection

Mold protection is critical to prevent catastrophic mold damage (see The Business Card Test Sidebar). With molds, requiring faster clamp speeds and larger moving masses, the ability to stop the platens from clamping on foreign objects between the platens has never been more important or more difficult.

Typically, a machine closes at an initial high speed to a given position, near the mold closed position. The machine then switches to a force limiting mode. In this mode the platens move at a fixed rate and the machine senses the resistance to reach the mold closed position. If the resistance exceeds the predetermined limit before it reaches the final mold closed position the mold will not clamp up. To sense small objects using this process it is critical that the machine is stiff and rigid so it does not compress or tip and give false closed readings. When large hydraulic cylinders, linkage-based clamps or unsupported platens are used to do the clamping, it is very difficult for these devices to sense the presence of a small thin object between the faces of the mold and then react in time to prevent building clamp tonnage. Once full tonnage is applied to the mold the trapped object can cause permanent and extensive damage to the mold, making it inoperable.

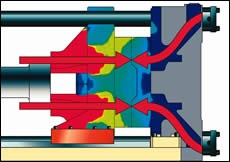

To improve mold protection sensitivity, especially on machines greater than 200 tons, the platen movement and the clamp up of the mold can be separated into two different circuits. In this case, a small, fast circuit can be used to move the platens and sense a mold interference before the large force clamping circuit is engaged. Using this method, a large mass can be quickly decelerated in a short distance and in time to prevent mold damage (see Figure 3, page 45).

Tonnage Distribution

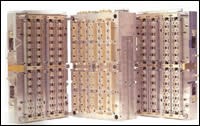

Maintaining an even force distribution over the entire mold face during the molding cycle is critical to prevent flash, reduce hobbing and ensure identical molding conditions to each cavity of the mold. Failing to provide this will cause the mold to be over-clamped to compensate for insufficient support, run slower or run with less than full cavitation due to part quality issues. Achieving a flat interface for the mold during build-up of clamp tonnage is difficult as it is a function of the mechanics of the clamping design (see Figure 4).

Ideally, clamp force should be applied evenly over the face of the mold. However, clamp force is delivered from links or cylinders to parts of the platens. Distributing this input over the entire face of both the moving and stationary platen evenly can be accomplished to a degree with thicker platens. This method reduces the deflection of the platens themselves, but does not even out the distribution of force. It also increases the weight of the moving masses, which reduces the speed and sensitivity of the system.

With the development of accurate finite analysis models of the injection molding process it has been possible to develop new dynamic cast platen designs which redistribute the loads evenly over the entire platen face. This results in a reduction in the required clamp tonnages and corresponds to even wear of the molds. Customers with these platen designs are seeing reductions of up to 40 percent less clamp tonnage, which is resulting in 100 percent increases in taper and vent life.

Injection and Shot Control

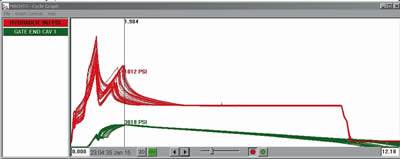

The development of closed-loop, PC-based control systems and drive technologies is changing the way that the plastic is controlled as it is recovered and injected into the cavities. Very fast microprocessors with short scan times working in unison with new drive technologies (electric and hydraulic) are allowing unprecedented control of injection profiles and recovery positions.

Precise control ensures that the shot injected into the cavity every cycle is exactly the same. This, in turn, reduces the injection pressures required to fill and over-pack the cavities to ensure full parts. If the mold sees even filling at optimal pressure it does not breathe and flex as much during peak injection pressures. This reduces the clamp tonnage required to eliminate flash. A mold under less stress from injection pressure and the counteracting clamp tonnage will last significantly longer and produce more quality parts before rework.

Machine Selection: Long-Term Strategy for Profitable Growth

Molds are a significant investment for all molders. Making sure that the tool is run optimally can be the difference between profit and loss on a job. It makes economic sense to do as much as possible to protect your tooling investments with a machine that enhances its life. This is not a short-term decision, but rather a philosophy for profitable molding and a strategy for attracting long-term, high-volume and stable business—just the type of work every molder longs for.

Related Content

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreRead Next

Understanding the Effect of Pressure in the Cavity

Molders offer a moving target for moldmakers to adjust to by producing parts with different cavity pressures.

Read MoreSetting Up a Robust Process Forever

Deciding how to process a product with the least amount of part variation over the long term.

Read More