Mid-Year Look at Technologies Available for Your Mold Shop

One of the key foundations of any successful business is the technology and equipment it implements to achieve a final product. The following suppliers are providing new and improved solutions that could advance your business.

As we mark the halfway point of 2024, it’s a good time to take a moment to step back and assess where everything is, and whether any improvements can be made. While this is a useful tip for your own personal growth, it’s also just as of importance for your work life. Are you an engineer, a technician, a manager, a business owner? Is your company meeting customer’s demands, lead times and so on? Does it (and your employees) have the equipment required to be successful? And have you set up your company to grow and evolve with the technology that you have?

I’m not here to tell you the answers to these questions — but I am going to tell you that there is no shortage of equipment that could be right for your business.

That is why, every month, MMT’s editors compile technology roundups like this one to make sure you know what kinds of technologies are out there. Read on to find out more.

Source | Progressive Components

Prehard Steel Undercut Style Extends Sprue Bushing Options

Progressive Components announces the recent expansion of its Extended Sprue Bushings line in a series called the Undercut Style, an off-the-shelf, standard option for single-cavity molds.

PET Injection Molder Introduces rPET Capabilities

Source | Husky Technologies

Husky Technologies has launched the HyPET6e molding platform. Building on the company’s flagship PET preform injection molding system, HyPET6e delivers a combination of system components meant to meet sustainable molding requirements, such as rPET capability, enhanced energy efficiency and closed-loop quality control.

Stainless Steel Cooling System Extended to US

Source | Hasco America

Hasco has extended its VA stainless steel cooling range to the U.S. system ZI, used for the reliable cooling of injection molds, whether for hot or cold water or cooling oil. Also used in cleanroom environments and for medical technology, these mold cooling elements are made from high-quality 1.4305 stainless steel. Robust, safe and easily coupled, they enable reliable and leak-proof temperature control.

Source | Platinum Tooling Technologies

Speed Increasers Promote High Spindle Speeds for Handling Thick, Large Workpieces

Platinum Tooling Technologies is now supplying this additional equipment from Henninger to North America, useful for drilling, tapping and milling mold applications, among others.

Read Next

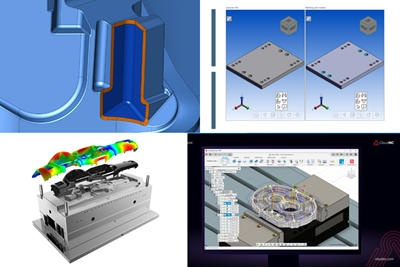

Design, Management Software Resources for Mold, Die Applications

As technology advances, so too do the options available to efficiently design molds or manage the data involved in their progress and production. Here’s a roundup of some of those solutions.

Read MoreMarch 2024 Technology Roundup Highlights

In this most recent roundup, MMT continues to present the breadth of new or proven technologies that target the moldmaking industry, from cutting tools to software to hot runner products, that have been shared this month.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More