Hot Runners

Mold Project Teaches Criticality of Design Phase Collab

Prestige Mold, Eastman Chemical Company, Mold-Masters (owned by Milacron LLC) and Pres-Tek Plastics joined forces on a project to solve customer challenges with producing small medical device parts made of Tritan™ copolyester with a multi-cavity hot runner mold. I spoke with Eastman's market development manager for medical devices to learn more about the Eastman-Prestige collaboration.

Read MoreCommon Sense Innovation and Moldmaker Collaboration

As I walked the aisles of NPE last month, taking in all the plastics-related technologies and solutions on display, two obvious trends emerged: logical innovation and moldmaker collaboration.

Read MoreSmart Tooling

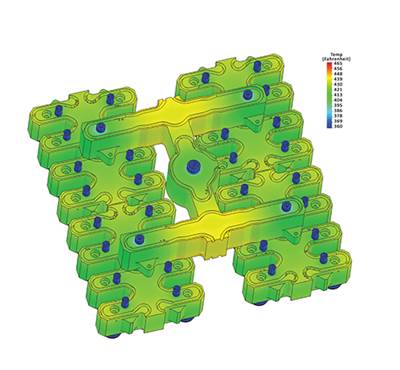

Combining cavity sensors with hot runner valve gate control yields new applications and greater process gains.

Read MoreReduce Part Failure with Melt Delivery Science

The best way to determine when naturally balanced, rheological managed and thermally balanced hot runner solutions are required as a single solution is to examine the science behind each approach.

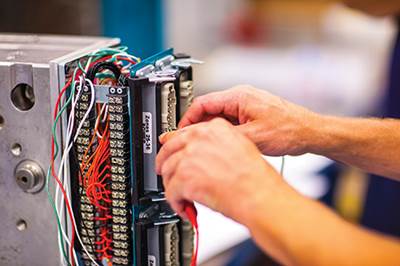

Read MoreControlling the Melt Delivery System Heat Source

Understanding the heating systems along the melt delivery path is critical to setting up a robust process and properly diagnosing problems.

Read MoreHot Manifold Repair: What’s so Tough about it?

Maintaining a typical hot runner system takes mold maintenance skills to the next level.

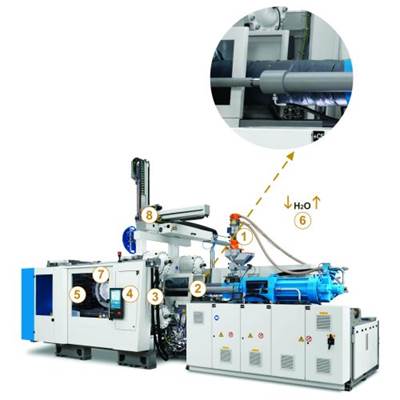

WatchThe Pellet Enters the Melt Delivery System

Choosing a hot or cold runner system is a decision for the molder and moldmaker that must balance the processing window with budget and time.

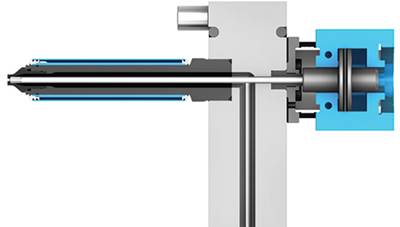

Read MoreInitial Pellet Contact is the Screw

Here’s what every moldmaker should know about an injection molding machine’s reciprocating screw, which is often misunderstood and applied to the process incorrectly.

Read MoreNo More Cooling Required

Moldmakers and molders can increase mold uptime using today’s cooling-free valve gate actuators.

Read MorePlastic Injection Molding Starts with the Pellet

This is the first article in a new series that will examine the injection molding process by breaking down the path a plastic pellet takes as it is transformed from Pellet 2 Part. It covers what every moldmaker should know about raw materials, including the fundamentals of viscosity curves, Melt Flow Index, Melt Flow Rate, shear and more.

Read More