Hot Runners

Improving Sequential Molding

For large injection-molded parts, a servo-driven valve gate system can improve surface finish and part performance.

Read MoreUsing Data to Improve Mold Performance

An easy way to get a snapshot of how a mold is operating is to run regular mold scans via a hot runner temperature controller.

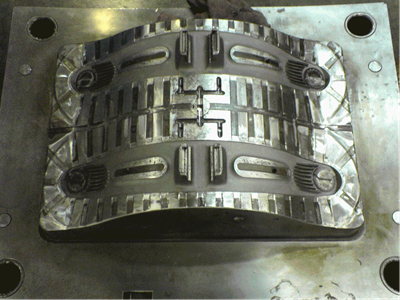

Read MoreSlideshow: Hot Runner Technology

Check out a few of the latest products in hot runner technology.

Read MoreMultiple Impact

Incorporating multiple-gate nozzles means smaller molds, small presses, a balanced fill rate, reduced residence time, temperature control and design flexibility.

Read MoreSetting a Standard in Hot Runner Design

Keeping hot runner system costs down is key to efficient injection mold design.

Read MoreDirect Side Gating

Mold builders and molders should carefully consider hot runner selection, as it dramatically impacts an injection molding system’s speed, quality and uptime.

Read MoreControlling Your Hot Runner Manifold System

Moldmakers and molders need to better understand modern hot runner controller technology to solve processing problems.

Read MoreThe Designer's Edge: More on Venting

Randy shares how his views on venting specs have changed since moving from the tool shop to the molding side of the business.

Read MoreThe Designer's Edge: Venting

Randy shares a real-world perspective on venting and exposes the true value of tool standards.

Read MoreMold Water System Basics

Molder to moldmaker: “If you want the project, you need to hit the targeted tooling costs.” Then oftentimes the moldmaker builds a tool that fits the budget, but does not have the best performance with regards to water. Here are some basics about the impact of mold's water system.

Read More

.jpg;maxWidth=300;quality=90)