Mold Project Teaches Criticality of Design Phase Collab

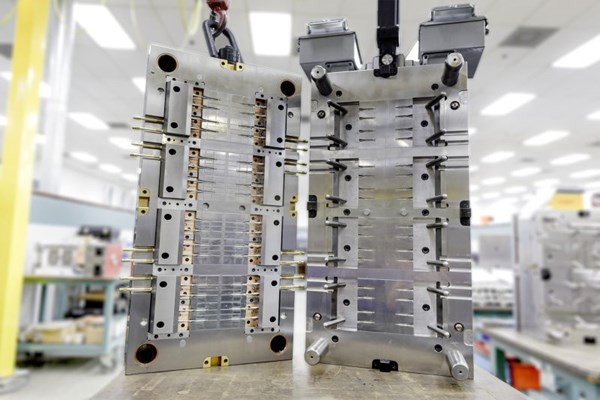

Prestige Mold, Eastman Chemical Company, Mold-Masters (owned by Milacron LLC) and Pres-Tek Plastics joined forces on a project to solve customer challenges with producing small medical device parts made of Tritan™ copolyester with a multi-cavity hot runner mold. I spoke with Eastman's market development manager for medical devices to learn more about the Eastman-Prestige collaboration.

Prestige Mold, Eastman Chemical Company, Mold-Masters (owned by Milacron LLC) and Pres-Tek Plastics joined forces on a project to solve customer challenges with producing small medical device parts made of Tritan™ copolyester with a multi-cavity hot runner mold. This project was showcased at NPE2015 last month and is on Eastman’s TritanMoldIt.com website, which was created for the purpose of knowledge sharing among the molding community.

I spoke with Ellen Turner, Eastman's market development manager for medical devices, to learn more about the Eastman-Prestige collaboration.

Christina Fuges: How did Eastman and Prestige get together? Why Prestige?

Ellen Turner: For this project, Eastman was looking to collaborate with a company to build a high-quality demonstration tool that had a good reputation in the market and a high level of expertise in tight-tolerance, multi-cavity tools. When you look at the combination of Prestige’s know-how and that Pres-Tek was located next door, you can perform all parts of the project in essentially one stop.

CF: Did Pres-Tek have any influence in Eastman's decision to work with Prestige in this project?

ET: Yes, they certainly did. It’s unusual to find a company that makes a tight-tolerance, high-precision, high-cavity mold. And they have a shop that makes a full validation.

CF: Will this collaboration with Prestige continue? If so, in what way?

ET: We continue to collaborate with them on specific projects with mutual customers. Plus, we’ve worked with Prestige to help us train some customers on our polymers. In the future, we see moldmakers as really the key to helping customers be very successful in molding Tritan.

CF: Has Eastman worked with Prestige before? If so, please explain.

ET: Previously, we really didn’t have a touch point with them other than we approached them and asked them if they knew Tritan. They had previously made a few things with Tritan, but we hadn’t collaborated to this extent before.

CF: Does Eastman have other moldmaker "partnerships"?

ET: We work with a lot of mold makers, in which we have interactions with them about how to design and produce a mold for copolyesters. We really don’t have a collaboration with any of them like we do with Prestige, but Eastman is open to expanding those relationships.

CF: What value does Eastman see in collaborating with moldmakers?

ET: The collaboration opens a lot of areas: it broadens both parties’ understanding of each others’ capabilities. Tritan is still a relatively new material in medical molding, especially in multi-cavity. We view Prestige not only as a collaborative partner, but also as a validation partner. Eastman has a good reputation in other markets. The two parties really help reinforce one another. In addition, working closely with moldmakers allows us to teach the criticality of collaborating early in the design phase of a project for Tritan to be successful in designing and molding with it.

CF: Any advice for moldmakers in terms of taking advantage of collaborative opportunities like this one?

ET: Do it if you can, and as often and early as you can. Really strive to reach an understanding of the material. At the same time, moldmakers can teach their craft to the material supplier. Really, it’s about learning from one another as it helps make you strong as you move forward. Take advantage of all those opportunities. We’re not experts in moldmaking, but we’re experts in Tritan. When you pair us up with those moldmaking experts, we can have much more successful projects.

Related Content

MMT Chats: A More Modern NPE “Made for You”

The Plastics Industry Association is making NPE 2024 a “can’t miss”’ experience with more of everything – education, exhibitors and networking! The PLASTICS Industry Association Chief Operating Officer Glenn Anderson and Director of Trade Show Marketing Damaris Piraino share what’s in store for attendees of next year’s May 6-10, 2024 in Orlando, Florida.

Read MoreTop 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreStrategies for Delivering a Qualified Talent Pipeline for Manufacturers

Insights into the importance of talent in maintaining national competitiveness, the impact of global events on the workforce and practical strategies for developing and implementing effective talent plans.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More