Hot Runners

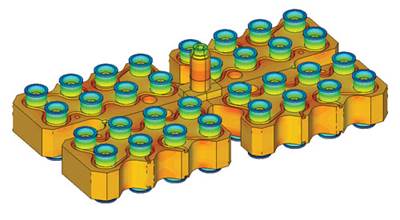

Energy Savings in Multi-Cavity Molds

Simplifying maintenance and energy savings in the development of hot runner systems for multi-cavity molds for medical applications.

Read MoreTemperature Control Boosts Hot Runner Productivity, Eliminates Burned Parts

“The controllers feature a system that ‘bakes out’ moisture within the heating element at every startup. This reduces downtime—and protects the mold.”

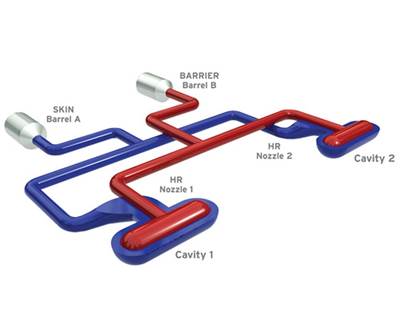

Read MoreIt’s Time to Reevaluate Co-Injection Technology

With the development of new resins, hot runners and controls technology, co-injection is positioned to move from a niche market application to mainstream acceptance in the upcoming years.

Read MoreCo-Injection in Action

Historically, co-injection workcells have been highly specialized dedicated systems with high capital cost to start with. Now there are new solutions coming on the market, which will allow molders and moldmakers to create co-injection systems at a radically different cost because they are now able to use their installed workcell base and standard molds for the solution.

WatchA Collaboration to Put “Collapse” on the Rise

“The idea behind Demo Day was let’s not just talk about the benefits of c-core technology, let’s build a mold so people can see up close the true capabilities of the DT Core as it molds a typical cap.”

Read MoreFive Critical Requirements for Hot Runner Cables

When you are developing your hot runner process, don’t forget the importance of the hot runner cable.

Read MoreStandardizing Short- and Long-Run Production

New hot sprue bushing technology makes it possible to replicate the full hot runner system for low-volume production.

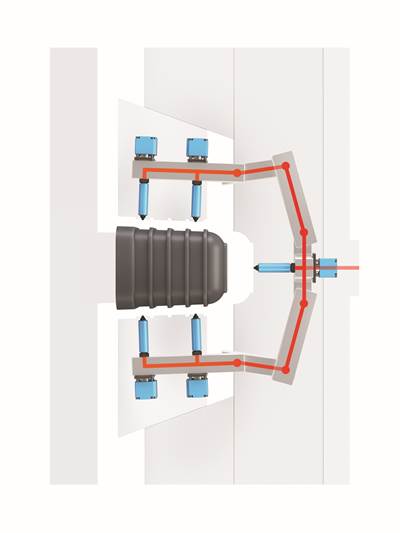

Read MoreSelecting a Valve Gate Hot Runner

A look at valve gate plate actuation technology for consistent part filling, excellent gate quality and close nozzle spacing.

Read More

.jpg;maxWidth=300;quality=90)