Hot Manifold Repair: What’s so Tough about it?

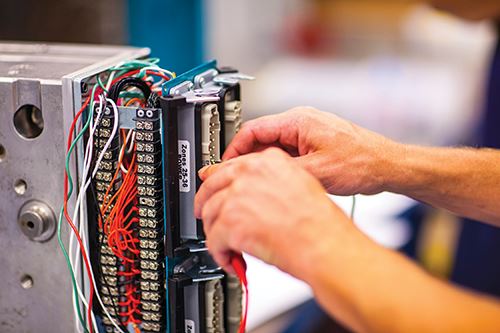

Maintaining a typical hot runner system takes mold maintenance skills to the next level.

There’s no denying it. Hot runner manifold repair can strike fear into the hearts of even seasoned repair technicians. As one who trains technicians on everything related to mold repair and maintenance, I’ve heard literally hundreds of horror stories about manifold catastrophes that drive stress up and profits down.

With manifold manufacturers predicting that 60 to 75 percent of all new molds will include hot manifolds of some type, it has become more evident that repair technicians will need more hands-on training to learn how to work on these touchy, but extremely cost-effective mold systems.

By training, I don’t mean parking a technician in front of a computer to listen to someone wax on about how things should be done while showing hot runner drawings and diagrams, or having the technician read hot runner maintenance manuals. I’m speaking about good, old-fashioned, hands-on technique training that can only be practiced and learned—with positive results—at a bench, under the guidance of hot runner journeymen.

Where Did All the Hand Skills Go?

In the repair arena, the level of hand skills and the ability

to work proficiently with precision tools is heading in the wrong direction. That there is a skills shortage in this country is an understatement. This term usually refers to the lack

of technical knowledge that is required to maintain expensive and advanced equipment, but it can also apply to mold-repair skills. The ability to make the hands do exactly what they should in mold repair is fading fast. It takes practice. But perhaps even more important is for repair technicians to learn sound bench techniques from which to grow.

For example, it’s been proven that quarterbacks can’t throw accurately if they have certain tendencies that don’t allow their feet, shoulders, hands and arms to be in the correct position as they release the ball. It’s the same for most tradesmen. Repair techs can’t control tools if they are using the wrong technique, not to mention the wrong tool. In addition, they often aren’t aware of bad habits within the technique, especially if they have never been properly trained.

Often, the skills missing are the physical kind that allow someone to read a set of micrometers, or gauge a tight or loose fit, or use sight or hearing to “read resistance” when using tools or machines. Not having these abilities will render us “tooling replacers” who are capable of very little precision or delicate work.

Shops have not consciously chosen to become tooling replacers as part of a maintenance strategy. Rather, it’s borne out of necessity as companies struggle to find people with hand skills. Products need to be molded and molds need to run, so just stick in new tooling and be done with it. The talent pool for experienced bench technicians is just not keeping up with demand.

Why Is Hot Runner Repair Difficult?

Hot runner work takes the required skills mentioned here to a higher level. Mistakes made and procedures not followed or simply overlooked can be catastrophic. All the economic efficiency that a hot runner system brings to the table is lost when it goes down for extended amounts of time and needs new heaters and thermocouples.

Whenever manifolds are disassembled for preventative maintenance or to repair issues that affect production/part quality, a few basic bench principles should be applied. Determine if the following basic rules of hot runner engagement are being practiced in your shop. If not, training is in order.

Basic Disassembly:

- Verify the maintenance plan before you start any work on the system. Are the cycles known?

- Review any images, data or tech-tip-type of instructions that can prevent mistakes and damage to person or mold.

- Before any work is done, map out the electrical system with an ohmmeter to verify or discover any existing problems with connectivity, grounding or resistance.

- Verify what tooling is on hand. Do you have spare heaters, thermal couples or other tooling that might be needed if things go wrong?

- Take pictures.

- Put the mold in the recommended position for disassembly. For valve pin systems, it’s best to heat up the nozzles and manifolds to take the valve pins out versus trying to muscle them out cold.

- Handle all tooling with caution. Don’t haphazardly pile tooling into a solvent pan to clean it. Instead, make and use tooling “boards” and rubber hoses to protect nozzle tips.

- When the rear clamp plate is removed, be sure to take height measurements at the four corners of the manifolds before anything is unbolted to use as a reference when re-assembling the manifold.

- Pay attention to everything. Develop a checklist:

– Bolts (missing, stripped, broken, difficult to remove)

– Wiring (paths, numbering, condition, splices, clips)

– What aligns the manifold with the plate?

– Plastic leakage (where, burned or fresh)

– Nozzle tips (dinged, broken, damaged)

– Valve pins (bent, broken, worn, reworked)

– Seal/O-ring condition and lubrication level.

Basic Assembly:

- Ensure that everything is clean and flat.

- Make sure all corrective actions (terms and tooling) have been documented.

- Look at the pictures you took during disassembly.

- Put away all brass, copper, aluminum and other “flaking” hammers. Use soft, cold-rolled-steel hammers instead.

- Pay attention to any resistance you feel during procedures that seems excessive. A bigger hammer might not be the best option.

- Manifold bolts should be “anti-seized” and torqued to either print specifications or bolt-size specifications.

- Re-check the dimensions at the four corners of the manifolds to verify flatness across the manifolds. For example, look for pinched wires and other things that could cause the manifold to not be in the proper position for tightening.

- Make sure all wire clips are back in place.

- Verify electrics with the ohmmeter before the rear clamp plate is re-installed, then verify again after. This is a quick procedure, even with high-cavitation molds.

- Button everything up and say a “Hail Mary.”

In both the disassembly and assembly stages, repair technicians need to develop a heightened sense of “feel” by using better tools and techniques. However, these repair technicians should not shoulder the whole responsibility for effective mold maintenance. Companies must recognize that the working environment of the repair shop, including shop design and knowledge sharing, has everything to do with improving the level of work that gets accomplished.

Related Content

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read More5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreHow to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreRead Next

Efficient Maintenance Requires a Calculated Plan

Advancing from a mold repair culture to a mold maintenance culture can only be fully supported with a companywide understanding of what the real costs are and what the real potential savings can be.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More