Hot Runners

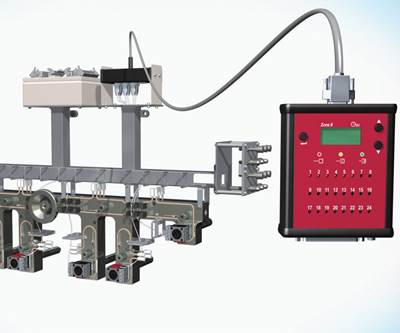

Modular Technology on Demand

An upgradable approach to flow-control technology offers flexibility and could help ease the decision on whether the technology is worth the investment.

Read MoreSLIDESHOW: Technology Showcase, After K

By all accounts K 2016 was a success. According to show management, attendees were delighted with the wealth of new technical developments presented by raw materials producers, machinery manufacturers and producers of semi-finished and technical parts. Here are some technology highlights.

Read MoreSLIDESHOW: Technology Showcase, A K 2016 Preview

As K 2016 quickly approaches, we’re providing a preview of a few of the products that will be featured there from October 19-26 in Düsseldorf, Germany.

Read MoreMultispeed Valve-Pin Control

Eliminating hesitation marks is easier and more cost-effective with multi-speed hydraulic technology.

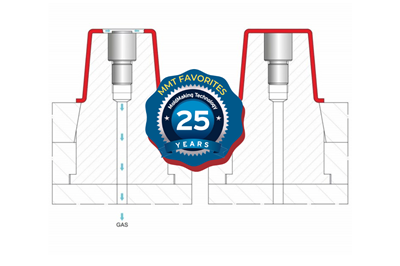

Read MoreVenting in Action

A dynamic (versus static) mold-venting valve helps resolve the most common effects of poor cavity venting.

WatchA Different Approach to Mold Venting

Alternative venting valves can help overcome standard mold venting limitations and improve mold performance.

Watch2016 Digital "Technology Review and Sourcing Guide" Available

If it's time to upgrade old equipment, try an alternative process, invest in a new strategy or just shop around, MoldMaking Technology’s annual Technology Review and Sourcing Guide is the perfect companion to your decision-making process.

Read MoreGetting Started with Hot Runner Maintenance

Developing basic cleaning and repair skills among in-house technicians should be the goal of every shop that runs hot runner systems.

Read MoreDesigner's Edge: Hydraulics for Slides, Ejection or Cores

Randy discusses tips and tricks for avoiding mold downtime when it comes to hydraulics for slides, ejection or cores and hot runner plugs or connections.

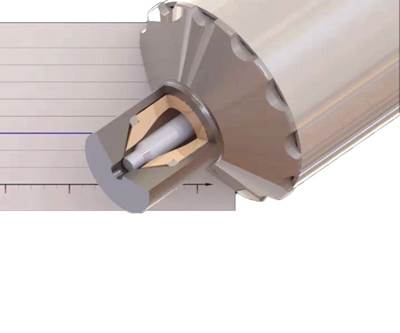

Read MoreProving the Advantages of a Servo-Driven Valve Gate System

One innovation for improving sequential injection molding centers around the use of servomotor technology.New servo-driven valve gate systems incorporate a toggle-type mechanism that operates the valve pin position at 90 degrees from the servomotor stroke.

Watch