The Pellet Enters the Melt Delivery System

Choosing a hot or cold runner system is a decision for the molder and moldmaker that must balance the processing window with budget and time.

There are two main types of melt delivery systems used in plastic injection molding—hot runner and cold runner—and many variables must be considered when choosing the right system for the job. But what’s the moldmaker’s role in choosing the appropriate system?

This decision is usually made by the molder before the request for quote (RFQ) is sent, but the impact of the decision is felt for years—three to five years in the automotive world and 10 to 15 in consumer products.

Tooling budgets focus primarily on material costs, labor and engineering time (mold flow, 3D modeling, toolpath programming), but they often do not take into consideration other costs that will be needed to get the project to the PPAP (production part approval process) date, where the part meets fit, function and appearance requirements. This is where the moldmaker can help influence the choice of melt delivery system.

A cold or hot runner will need to be serviced during the later phases of production, and, typically, no dollars are budgeted for this work. Meanwhile, the molder—the moldmaker’s customer—is fighting quality issues and having trouble meeting on-time delivery deadlines. What can you, the moldmaker, do to help alleviate these issues?

Get involved early. Build customer relationships based on confidence and trust from the beginning. A moldmaker who points out the potential issues and makes recommendations for the right design features adds value. In some extreme cases, you may need to decline a project because you know the current budget is ultimately setting up the molder to fail. For example, an injection molder who insists that the tooling budget is fixed may end up spending future capacity, profits and resources. Educating the customer on these unpredictable costs will help both the molder and you. Ultimately, if you do accept a job with such a fixed tooling budget, you will be responsible for the mold’s performance, despite your earlier recommendations.

The decision on whether to use a cold or hot runner system is one such critical recommendation. During this decision-making process, the focus should turn away from the mold and toward the molding process. You need to figure out how to give the process engineer the largest processing window while also considering the budget and time. It’s a balancing act.

The processing window should allow for molding variables such as temperature (seasonal, water, etc.), machine variations, resin viscosity variation and operator error (incorrectly changing a setting). A cold or hot runner system will work for many projects, but the appropriate choice can only be made when the application (part quality) is considered.

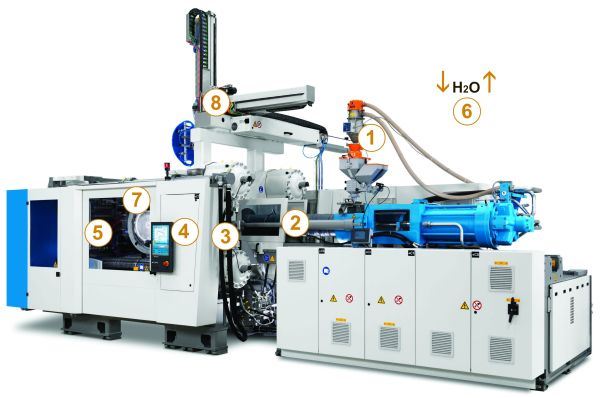

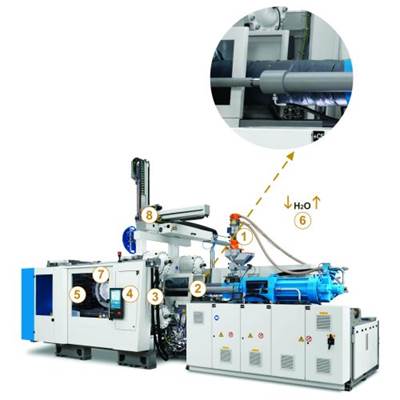

In one particular Tier 1 injection molder’s application, the job calls for 200,000 parts per year to be made from an engineered, 40-percent-mineral-filled Nylon 6 resin (no weekly projections were given for the quote.) The mold is targeted to run in a 250-ton press with modern robotics and end-of-arm tooling (EOAT). The tooling budget is $70,000. Specifications include two or three tight dimensions and a Class A surface finish (paint, chrome, etc.).

From what you learned in January’s P2P article on resins, you probably realize that this application would most likely fail. Generally, you cannot use mineral-filled Nylon in Class A applications. Let’s adjust the application by removing the Class A requirement and making it a non-visible part with the same dimensional requirements.

Here are some factors to consider when selecting a cold runner or hot runner system for a job like this one:

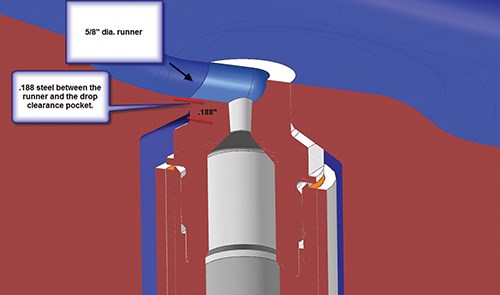

• Gating type and location. Experience is priceless when it comes to making this decision, as there are many choices, including sub-gates, tab gates, lifter gates, slide gates, three-plate molds and gating direct onto the part. Prior to finalizing the mold design, a filling analysis is recommended for validation. Keep in mind the application requirements will influence this decision greatly. For example, part requirements take the overall assembly interaction into consideration, such as the part’s gate area, vestige height, dimples and the de-gated area.

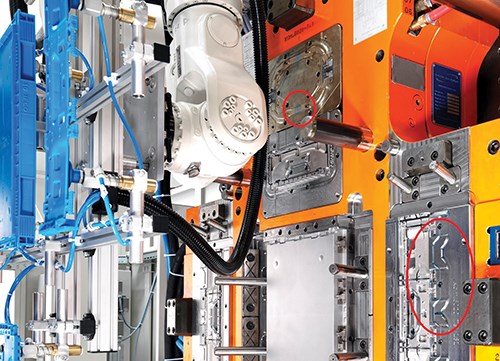

• A face-removable gate-inserted area made from wear-resistant material. This is ideal in applications where high wear of the gating area is expected. Part requirements, such as no seam lines, may not allow for this. A good program manager working with the end customer is a huge asset in this situation. It’s all about communication and relationships.

• Regrind. What is the allowable percentage? What percentage of the total shot is the discarded runner?

• Gate performance and consistency (gate size and shape over time). These are the drivers in the decision, although runner length (cavity spacing and gate location) and diameter are also considerations.

• Cold sprue or hot drop. This is also referred to as a hot-to-cold system, or hot runner system to a cold runner system.

When specifically selecting a hot runner system, consider the following:

• Accurate temperature control along with the melt delivery path, and properly operating power cables and hot runner controllers.

• An equal (or smaller) number of heat zones in the system and zones on your hot runner controller.

• The control of the valve gate timing in relation to the injection sequence when using a valve-gated hot runner system. When the pin opens there should be no plastic pressure on the valve pin. This is true in single- and multi-drop valve gate applications. It’s even more critical when molding shear-sensitive engineered resins.

• Electrical and valve gate connection requirements for mounting locations, space consumed and wire/tubing channels that are necessary for connecting everything in the mold. These channels can be an issue when trying to keep support and the correct number of mounting holes in the plate system.

Variations of these considerations are virtually endless, and they are dependent upon the application and molder requirements. The most important takeaway is that you execute an internal decision-making process that factors in the needs of everyone involved: the moldmaker, molder and end customer.

Related Content

How to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreTips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreRead Next

Initial Pellet Contact is the Screw

Here’s what every moldmaker should know about an injection molding machine’s reciprocating screw, which is often misunderstood and applied to the process incorrectly.

Read MorePlastic Injection Molding Starts with the Pellet

This is the first article in a new series that will examine the injection molding process by breaking down the path a plastic pellet takes as it is transformed from Pellet 2 Part. It covers what every moldmaker should know about raw materials, including the fundamentals of viscosity curves, Melt Flow Index, Melt Flow Rate, shear and more.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More