Reduce Part Failure with Melt Delivery Science

The best way to determine when naturally balanced, rheological managed and thermally balanced hot runner solutions are required as a single solution is to examine the science behind each approach.

The best way to determine when naturally balanced, rheological managed and thermally balanced hot runner solutions are required as a single solution is to examine the science behind each approach.

Naturally balanced hot runner systems are used in multi-cavity mold applications where all the parts are the same. They are designed with equidistant flow paths and flow diameters held to tolerance. These applications allow for the use of manifolds with multi-level flow paths to achieve equal flow lengths to each of the cavities or the use of a bridge manifold.

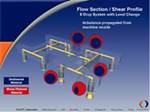

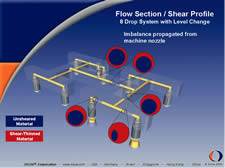

Rheological managed hot runner systems are based on the flow of matter from which the Hagen–Poiseuille equation was developed. Still used today to calculate deltas in pressure drop for non-Newtonian fluids such as plastic, this equation has been recognized as essential to achieving true cavity-fill management by mapping dynamic viscosity variations as the plastic flows from the machine barrel into a hot runner system and then into the part. Mapping the distribution of the relative high and low plastic laminates and then managing those laminates so they are homogenously delivered to the cavity is crucial to the success of some applications.

Thermally balanced hot runner systems are designed to be thermally stable and homogenous throughout the manifolds and nozzles. This stability is easy to achieve when a system is sitting on a test bench, thermally isolated from surface contact that will influence heat distribution, but it is not so easy when the system is within a mold and in contact with various surfaces and cooling elements. Finite element analysis (FEA) and the right temperature controllers can be used to help meet this goal.

To illustrate the successful use of these three applied sciences as an all-in-one solution, let’s look at a specific 32-cavity, direct-valve-gated, preform mold application. The mold builder could not understand why the medical preform OEM/molder took “perfectly fine” molds and retrofitted the existing hot runner systems. To the mold builder’s knowledge, the molds performed well, but short-shot analysis proved otherwise. In addition, the delta in part fill directly corresponded to the fracturing failure of the bottles in the blow molding process.

The failure rate the molder was experiencing was considered “acceptable” until a deeper study of the fill patterns in relation to the fracture during the blow molding process proved that there was a direct correlation between bottle failure and preform filling patterns.

The existing molds used hot runner systems with naturally balanced and thermally balanced manifolds, but application of melt management science was missing. After the molder was introduced to rheological imbalances and the scientific approach to melt management, an investment in a mold using all three runner system approaches was made, and the results were favorable. This change yielded a substantial decrease in part-to-part weight variance and improved fill pattern in all stages of progressive short-shots. This, in turn, led to a reduction in part failure during the blow molding process, a six-figure material savings in the first year, faster mold startups and a more open process window.

Related Content

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreRead Next

Improving Shear-Induced Imbalance in Hot Runner Systems

Even melt distribution and balanced filling to and across all cavities while avoiding restrictive mixers is possible with hot runner manifold construction that incorporates a melt rotation design.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More