Design & Mfg. Software

Seeing the Industry with a New Perspective

Last week I attended Plastec West in Anaheim, California (what a nice break from frigid temps in Chicago!). It was my first trade show as senior editor of MoldMaking Technology versus attending as a public relations manager for plastics industry suppliers, and I enjoyed seeing everything with a new perspective.

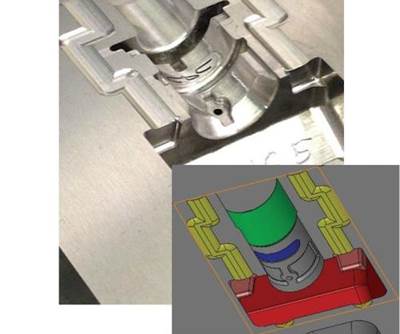

Read MoreHigh Accuracy and Efficiency CAM System Speeds Mold Building

The ability to machine smaller details into molds has reduced or often even eliminated the need for secondary surface finish operations.

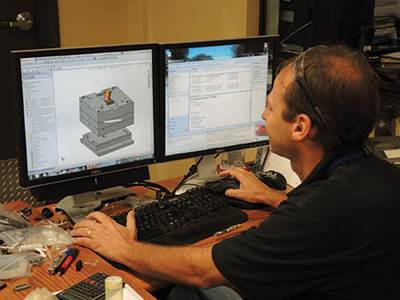

Read MoreExpanded CAD/CAM Usage

Expanded CAD/CAM usage improves processes, standardization, machine utilization and output.

Read MoreWhat is Your Plastic Pain Point?

Many will agree that one of the most frustrating aspects of plastic injection molding is warping. With that in mind MMT joined a Moldflow engineering services provider in a webinar to show how the manufacture of plastic parts affects their final shape. Take a look at three key questions asked during the discussion, and then view the recording.

Read MoreDo You Want to Know Why Plastic Parts Warp?

I have worked with Tim Lankisch, director of engineering at CAE Services on numerous technical articles and educational videos in MMT focused on the value of simulation. Yesterday Tim came off the printed page and went live in an MMT webinar that analyzed why plastic parts warp. View archived recording now.

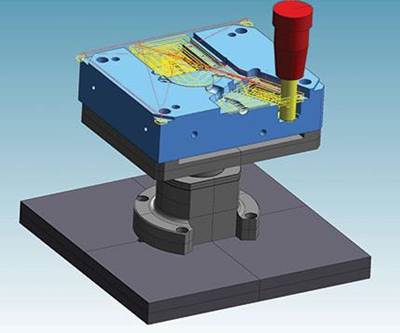

Read MoreRedefining CAM Technology for Moldmakers

Tool paths that dynamically adjust tool motion allow faster, safer machining without the need for high-speed equipment.

WatchReusing CAD Data

A true direct modeler can help mold builders work more easily with customer design data.

Read MoreCAM Automation is a Process, not a Goal

Automated NC programming requires a strategy to yield improved productivity, quality and consistency.

Read MoreFrom Bottleneck to Project Accelerator

Laser scanning provides new inspection options and a faster alternative to CMM for this engineering and mold manufacturing company.

Read MoreMinimizing Costly Tooling Issues

Properly reviewing a mold design before manufacture can help avoid new tooling issues.

Read More