Design & Mfg. Software

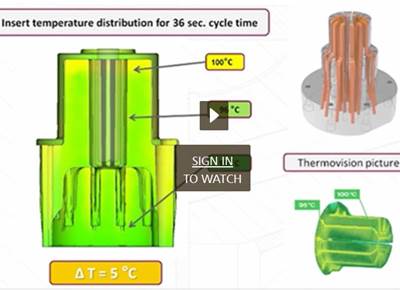

Practical Considerations for Conformal Cooling Designs

If you are looking for a comprehensive analysis of cooling design rules for additive manufacturing, check out this webinar.

Read MoreGet More Coolant Flow Through Smaller Bubblers

This method for calculating the size of nonround water passages is designed to increase coolant flow, and reduce pressure loss and cycle time.

Read MoreCircle Segment Tools and Toolpaths in Action

To take advantage of circle segment cutting tools, the programmer/machinist must generate sophisticated programs that continuously present the tool at a precise angle that is dependent on the slope of surface to be finished and the shape of the tool at any given point in the program.

WatchA Strategy for Better Mold Finishes

Combining advanced tool geometry and complementary CAM tool paths can reduce finish cycle times and improve surface quality.

Read MoreBeaumont Technologies Acquires Autodesk MoldFlow’s Material Characterization Business

Beaumont Technologies, Inc. has completed the acquisition of the Autodesk MoldFlow material characterization business that services North America and Europe. The operations, laboratory equipment and proprietary software will be transferred from Ithaca, NY to a new facility in Erie, PA where Beaumont is headquartered.

Read MoreThrowback Thursday: Liquid Silicone Rubber Molding Simulation

According to this week’s Throwback Thursday article titled “Liquid Silicone Rubber Molding Simulation”, which was published in January 2011, the use of simulation technology for LSR molds can be quite advantageous.

Read MoreHow Do You Validate Your Molds?

“Part simulation is fast. It’s something that can be done up front without impacting the overall development time."

Read MoreWEBINAR: Validating Your Mold Using Moldflow Data

Autodesk will present a free webinar on December 7 titled "Validating Your Mold: Making Good, Informed Decisions Using Moldflow.

Read MoreThrowback Thursday: The Science of Simulation

From evaluating part, mold and process designs and improving mold cooling to reducing plastic part warpage and determining the best gate locations, simulation plays a key role. MMT has provided a series of articles on just these topics, which I thought I'd share.

Read MoreChallenges of Multi-Cavity Co-Injection Molding

Simulation shows that, to be effective, these types of molds must be designed with consideration for how the materials will be distributed throughout them.

Read More