Design & Mfg. Software

TBT: Integrating Electrode Production

Many companies have an amazing setup in their shops and the machines are running day and night. But one thing still stands out for even the most advanced shops: how slow the EDM process can be.

Read MoreProject-Based Learning – The Rest of the Story

In this month’s issue of MMT, I wrote about an instructor’s strategy for teaching his mechanical engineering students about moldmaking via project-based learning. I couldn’t include absolutely everything this instructor teaches his students, so I thought I’d blog about it.

Read MoreUsing CAD/CAM for Product Development

To show the value of CAD/CAM software in research and development projects, I wanted to share this story that was sent to me about an Italian plastic injection mold builder that combines craftsmanship with current technologies to offer fully integrated project management.

Read MoreDesigning Molds, Building Futures

Wes Cobb, president of Technical Design Associates Inc. in Brevard, North Carolina, is the Society of Plastics Engineers (SPE) Mold Technologies Division’s 2016 Mold Designer of the Year.

Read MoreRobust Process and Part Design: How Do You Ensure Success?

Using DOE with Moldflow has grown more popular in recent years because of its ability to optimize part manufacturability, according to Jeff Higgins from Autodesk, who recently conducted a webinar on the topic for MMT readers. Today, we’re offering some highlights from the webinar based on the many questions Jeff fielded and answered for attendees.

Read More2016 Digital "Technology Review and Sourcing Guide" Available

If it's time to upgrade old equipment, try an alternative process, invest in a new strategy or just shop around, MoldMaking Technology’s annual Technology Review and Sourcing Guide is the perfect companion to your decision-making process.

Read MoreAre You Optimizing Part Design and Manufacturability?

Autodesk presented a free webinar titled “Using the Power of DOE to Design Process and Part Improvement”. If you missed it, you can still access it here.

Read MoreAIM-ing High to Serve Medical Market

During my recent travels, of which there’s been quite a bit, I had the opportunity to visit AIM Plastics in Clinton Township, Michigan, where a whole lot of medical molding is going on.

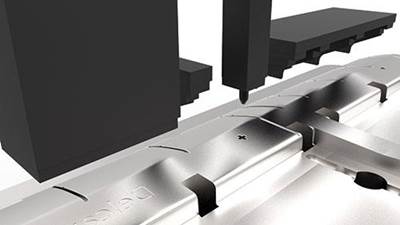

Read MoreReducing Risk in Lights-Out Machining

Surface-based CAM software can increase accuracy and make unattended machining a possibility for shops that have avoided it in the past.

Read MoreEnhanced Decision-Making

Collaborative manufacturing, combined with systematic injection molding training, can help reduce the costs and time associated with design for manufacturing.

Read More