Do You Want to Know Why Plastic Parts Warp?

I have worked with Tim Lankisch, director of engineering at CAE Services on numerous technical articles and educational videos in MMT focused on the value of simulation. Yesterday Tim came off the printed page and went live in an MMT webinar that analyzed why plastic parts warp. View archived recording now.

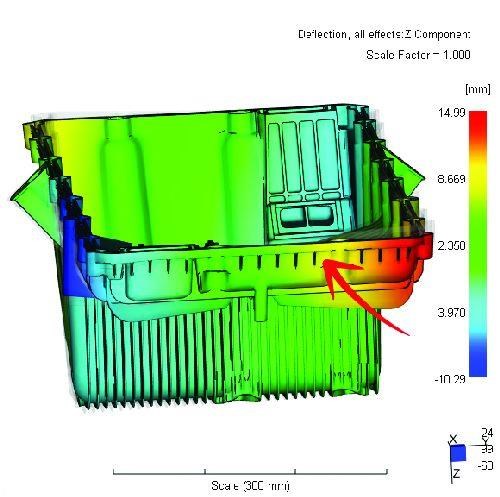

I have worked with Tim Lankisch, director of engineering at CAE Services on numerous technical articles and educational videos in MMT focused on the value of simulation. Topics have included using simulation to control flow in your injection molds, to bias your mold and reduce warpage, to predict high-conductivity insert performance and to determine the right valve gate sequence, to name of few. Yesterday Tim came off the printed page and went live in an MMT webinar that analyzed why plastic parts warp. In this webinar, Tim helped attendees understand how the manufacture of plastic parts affects their final shape. Click here for the archived recording.

Related Content

-

Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

.jpg;maxWidth=300;quality=90)