Design & Mfg. Software

CAM Software/Machine Matchup Saves Time, Boosts Efficiency

A five-axis machining center and better CAM software helped this mold shop dramatically improve throughput and profitability.

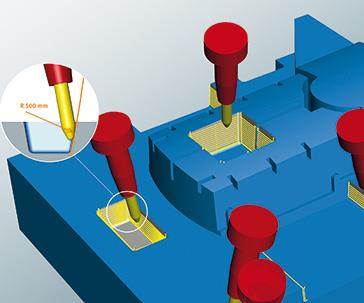

Read MoreBroadening CAM Applications for Barrel Cutters

This alternative cutting tool geometry, along with the right CAM software, can help moldmakers reduce finish-machining times.

Watch5X Tangent Plane Machining

The ball end of a barrel cutter cleaning a corner feature, and then the barrel cutter quickly covers the surface.

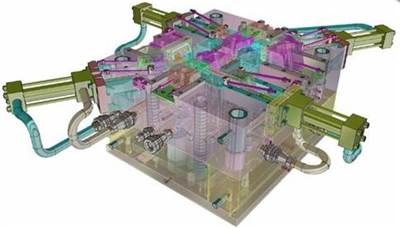

WatchWhat Do You Really Know about Mold Cooling?

Do you ever ask yourself why cycle time matters? Although the level of impact may vary across the supply chain, one thing is certain: reducing cycle times can lead to hidden cost savings. And with cooling and recovery making up more than 80 percent of the injection molding cycle, it is the perfect place for improvement to help reduce cycle times. Listen to this webinar to learn how to achieve optimal cooling through analysis.

Read MoreHave Designs on Conformal Cooling?

This Wednesday, April 27, MMT will host a webinar titled Practical Considerations for Conformal Cooling Designs.

Read MoreEliminate Software Clutter

An all-in-one mold design strategy can streamline the mold building process and increase accuracy.

Read MoreIntegrated Software Speeds End-to-End Moldmaking Operations

Cimatron CAD/CAM software from 3D Systems helped PTI Engineered Plastics simplify the flow of its work from design to production.

WatchCooling Is a Hot Topic

Mold cooling is one of the most important elements to mold productivity because it can greatly impact cycle time and part quality, which of course affect the bottom line ... your profitability. Check out these two upcoming webinars that tackle a variety of mold cooling challenges and solutions.

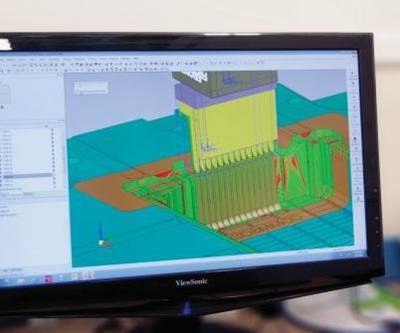

Read MoreToolpath Verification Optimizes CNC Machining Productivity

One shop estimates that the addition of Vericut software has helped it increase throughput as much as 20-30 percent.

Read MoreRough and Tough

What you don’t know about high-efficiency roughing versus high-speed roughing could be costing you money.

Watch