Design & Mfg. Software

Throwback Thursday: Reusing CAD Data

This Throwback Thursday blog is focused on CAD data and how designers can better work with customers’ CAD designs without “reinventing the wheel,” so to speak.

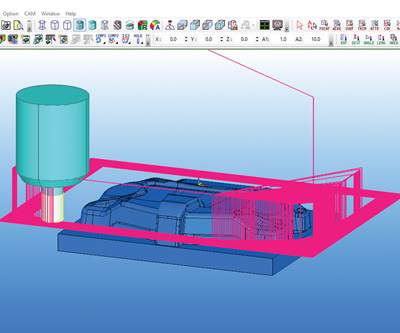

Read MoreLeveraging CAD/CAM Advances

Often-overlooked software tools can enhance moldmaking business competitiveness.

WatchTechnology Showcase: Case Studies for MoldMaking

It’s time for another foray into past case study features that have been published in MoldMaking Technology Magazine.

Read MoreCavity Pressure Selection Options and Solutions

According to RJG Consultant and Trainer Shane Vandekerkhof, whether you are a first-time user or a seasoned veteran, cavity pressure selection and placement can at times be a confusing decision. Here is a look at the options available to fit your application to make you successful.

Read MoreTechnology Showcase: Machining, AM and Software

With Amerimold in our rear-view mirror for the time being, there are still several new products that have been released, or will be soon, to bring to MMT readers’ attention.

Read MoreAmerimold 2017: Plastics Exhibitors Promoted Products, Too

Amerimold had it all this year—or should I say it had MORE than ever before. While metalworking tools, materials and systems reigned supreme, the plastics side of the equation was also well represented.

Read More2017 Leadtime Leader Awards Winner: Graphic Tool Corp.

Leadership changes set this mold manufacturer on a path of renewed purpose, fueled by data-driven, lean methodologies and deliberate, quality-controlled production.

Watch2017 Leadtime Leader Awards Honorable Mention: Concours Mold Inc.

This Canadian mold manufacturer identifies teamwork and quality as critical to its ability to drive continued success.

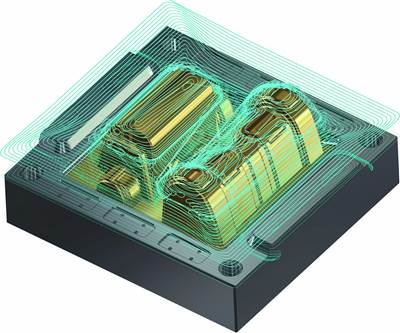

Read MoreConformal Water Line Design Guidelines

Principles for creating conventional water lines are the foundation for efficient and effective conformal cooling line design.

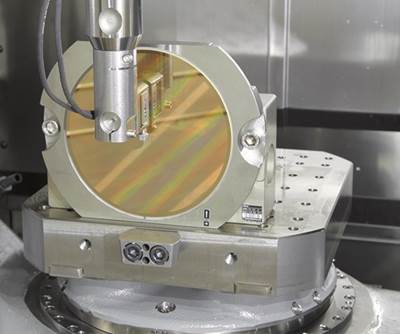

Read MoreStepping Up to the Challenge

This roughing strategy helps maximize metal removal rates and reduce roughing cycle times.

Read More