Expanded CAD/CAM Usage

Expanded CAD/CAM usage improves processes, standardization, machine utilization and output.

For Omega Tool Corp., an Oldcastle, Ontario, Canada-based moldmaker, good isn’t good enough. The company aims to foster a culture of continuous improvement and innovation, centering its focus on servicing and selling to customers who expect flawless execution. That execution requires the right technology, for which Omega says it seeks out the right partners.

One such partner ended up being manufacturing industry consulting firm Harbour Results Inc. of Southfield, Michigan, which provides assessments and reports on the automotive tool, die and mold industry. As a result of a report identifying OEMs looking to consolidate their tooling spending with fewer suppliers, Harbour was asked to qualify key tool, die and mold shops that were manufacturing products for Ford. This was done via a standardized two-day assessment eventually involving 180 different facilities around the globe, including Omega.

As a result of this assessment, Omega contracted with Harbour to refresh its long-term business strategy with the goal of adding more value and enhancing its competitiveness. Some of its objectives included upgrading plant-floor equipment, improving machine throughput, establishing standards and implementing those standards on the plant floor. Omega also found a new ally in its endeavors in CAD/CAM supplier Tebis America Inc. of Troy, Michigan.

Omega had already been successfully using Tebis software when in 2013 it called in a team of Tebis consultants from Germany to analyze Omega’s processes and benchmark them against a global peer group. These experts offered recommendations in the areas of process, standardization, increased machine utilization and output. They wanted to explore ways in which an expanded use of Tebis software and its approach to manufacturing could help Omega achieve the competitiveness goals outlined in its five-year plan.

The Simulation Advantage

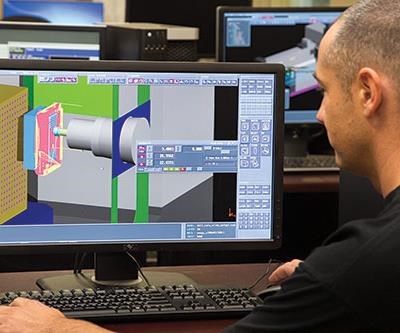

Omega wasn’t using simulation at all until it acquired the Tebis simulation system, which is designed to optimize machine operations by enabling users to identify and avoid possible collisions between component and tool geometry, check tool lengths before NC program calculation, and interactively define the optimum tilt direction. In addition, the system’s material removal simulation is intended to enable users to realistically assess surface qualities. Omega says all of this has had a tremendous impact on its operations.

The software tools are particularly useful when the company employs full five-axis simultaneous milling. They enable users to perform a detailed analysis of the tilt directions for the tool before they calculate an NC program, also taking head geometry and machine kinematics into account. Collision avoidance calculations include the holder components defined in the tool library. The simulator checks all machine components and limit switches.

“This not only lets us optimize machining, but it saves on programming time as well,” says Martin Chaput, Omega’s resource utilization manager. “Using the simulator has resulted in huge savings, because it allows us to maximize the utilization of our equipment and increase initial throughput.” He cites, for example, the fact that the company can now run jobs on its smaller machines that had formerly been reserved for larger machines with more costly run times in order to be sure to avoid reaching a machine limit. The software provides precise information about tool and fixture dimensions, and about how various components dynamically interact with a machining program.

“Additional downstream effects include improved accuracy, less rework and a reduction in spotting and fitting time because of the heightened accuracy,” Chaput notes. “It has helped us achieve excellent, and very predictable, surface finishes. Plus, it’s easy to learn and use.”

Omega also uses the simulation for offline programming and to check run times, which helps improve scheduling and machine utilization. Other shops might use simulation through a third party, transferring data into and out of their CAD/CAM systems, but this can slow programming and increases the opportunities for error. Omega is able to avoid this challenge, as the simulation is fully integrated in the Tebis suite of software tools.

Banking on Data

Information and data are valuable in today’s competitive manufacturing environment. To get more of it, the company introduced an in-process measuring procedure for defined features, as well as free-form measurement on the shop floor and machining centers. This data then is incorporated into the Tebis software’s MPoint surface measurement module, which checks for variance between the workpiece and CAD geometry, and then allows the user to make any necessary corrections in real time.

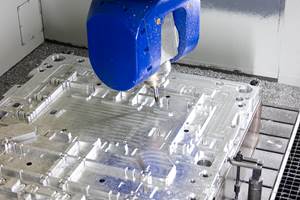

Increasingly, Omega’s workpieces are the product of complex, five-axis milling programs, COO Delko Prebeg says. Some CAM software packages struggle with large five-axis parts, because such parts generally entail a large amount of data that can slow it down. The Tebis software includes algorithms designed to quickly handle massive amounts of data, however. It also provides smooth machine movements for improved surface finishes.

Omega also now does a lot of “head work,” or 3+2-axis tip-angle work. “In machining large parts, it is often necessary to tip the machine head in order to adjust the machining angle,” explains Vernon Benson, a Tebis account manager. “Any time you have to change the angle or vector of the tool, you are adding a lot of complexity that can slow down your software, but Tebis can handle this.

“Ours isn’t the only system that can handle 3+2-axis tip-angle work, but we bring something new to the party. You can click on the machine head or the tool and simulate its operation, make adjustments on the fly, and send the amended or edited program back to the machine.”

In keeping with its vision of data as a key indicator of the strategic performance enhancements that the company is committed to, Omega instituted a resource tracking system to monitor machine utilization. The Tebis system is interfaced within the resource dashboard so that shopfloor personnel can access relevant CAD/CAM data.

“The system tracks machine efficiency and availability, which translates into better machine utilization, and that is central to our plans for moving forward,” Prebeg says. “Typically, companies run less-than-desirable capacities. After working with Tebis, as well as the other initiatives we’ve undertaken, we are running at over 90-percent utilization rates.” With the aid of the Tebis Multiple Setup module, as well as shuttles and material-handling robots, Prebeg says he is confident that figure will further improve. It already has been accompanied by a 10-percent reduction in total machining time required on any given job compared to the previous year, while overall productivity has increased by about 30 percent in the last two years, he says. Machine throughput has also drastically improved. In addition, a significant portion of outsourced machining has been brought back in-house. Engineering standardization has also proceeded, with all programming done in the same Tebis template style.

Omega now is working with Tebis to optimize cutter paths and reduce air cutting, planning to continue to push the envelope for what it can do.

Related Content

True Five-Axis Machine Yields More Throughput, Greater Productivity

CDM Tool & Mfg. Co. LLC increased shop capacity thanks to a versatile high-speed/high-accuracy five-axis Fooke mill capable of cutting very large workpieces quickly and accurately with fewer setups.

Read MoreHow to Clean and Maintain Molds With Intricate Conformal Cooling Channels

A water-based, eco-friendly plastic mold cleaning system helps Rankine-Hinman Manufacturing restore flow rates and avoid big-ticket failures on complex and costly molds.

Read MoreLarge Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read MoreIn "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.

Read MoreRead Next

CAD/CAM Upgrades Speed, Simplify Tool Build

A surfacing module and NC template technology are among the software features that help this mold manufacturer unleash the full potential of its equipment and its staff.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More