CAM-TOOL CAD/CAM Software

CGS North America, Inc.

4-2160 Fasan Dr.

Oldcastle, ON N0R 1L0 CA

866-389-3044 | 519-737-6009

info@camtool.com

camtool.com

About CAM-TOOL CAD/CAM Software

CGS North America is a leading provider of advanced CAD/CAM solutions, specializing in CAM-TOOL and QuickQuote mold quoting software. CAM-TOOL is a premium system tailored for the Manufacturing Tooling Industry, offering unmatched precision and functionality to meet the complex needs of Mold & Die builders. Our surface-based CAM engine is what truly sets CAM-TOOL apart, enhancing tool life, improving surface finish, and reducing EDM, spotting, and polishing time. It excels in hard steel applications, even when using tooling with high length-to-diameter ratios, ensuring superior performance in challenging scenarios.

In addition to CAM-TOOL, CGS North America offers QuickQuote, a powerful mold quoting software designed for quick and accurate estimates, further streamlining the production process. With our innovative solutions and dedicated support, we empower manufacturers to achieve greater efficiency, precision, and productivity.

IS THIS YOUR COMPANY?

As Seen On MoldMaking Technology

CAM-TOOL CAD/CAM Software Supplies the Following Products

- CAD (Computer Aided Design)

- CAM (Computer Aided Manufacturing)

- CNC Software

- Mold Quoting Software

- NC Simulation and Verification Software

Trade Names Offered by CAM-TOOL CAD/CAM Software

Editorial, News, and Products

-

AI Increases Efficiency for CAM Programming

Cam-Tool, CAD/CAM software from CGS North America pairs its existing, powerful templates with a new, user-driven AI technology, to increase efficiency and adaptability for CAM programming.

-

2024 Most-Viewed Products

A comprehensive dive into 2024’s most-viewed products, as revealed through MMT's analytics. This review highlights the most popular products, ranging from technologies, services, softwares and more from this past year.

-

Innovative Technology for Your Mold Shop at IMTS 2024: Part 1

MoldMaking Technology highlights a variety of innovative applications featured this year at IMTS 2024. From software solutions to new machines and services, dive into this comprehensive guide to best equip your mold shop.

-

CAD/CAM Software Update Further Streamlines Moldmaking Efficiencies

IMTS 2024: CAM-Tool V20 is presented by CGS North America, combining efficiency, precision and advanced AI capabilities to better tailor to specific mold builder needs.

-

Design, Management Software Resources for Mold, Die Applications

As technology advances, so too do the options available to efficiently design molds or manage the data involved in their progress and production. Here’s a roundup of some of those solutions.

-

Optimized Five-Axis Machining Operations Guided by Moldmaking-Focused CAD/CAM Software

Integration of CGS North America’s CAM-Tool software helps elevate accuracy, surface finish quality and overall efficiency in mold and die production.

-

Moldmaking, the Relentless Pursuit of Innovation … Oh Yeah!

Innovation was at the root of the presentation lineup for the 2023 MoldMaking Conference, which included a heavy focus on automation, collaboration and communication, as well as mold design, talent development, reshoring and sustainability.

-

MoldMaking Conference Session Spotlight: Software

Want to learn how to leverage CAD/CAM to streamline your moldmaking process or how to engineer cooling efficiency?

-

Software Technology to Meet Moldmaking Challenges

Featured in this technology roundup are software solutions that can provide and improve design and manufacturing operations or data management practices during the manufacture of a mold.

-

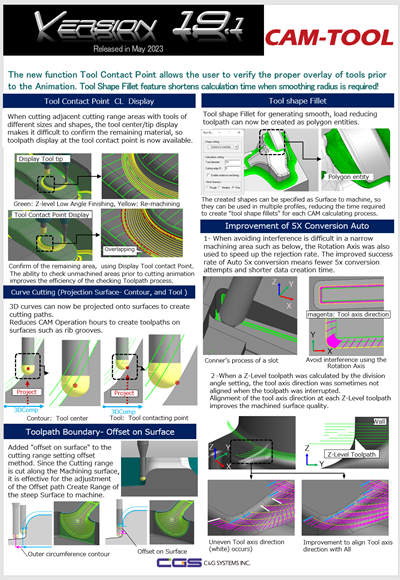

CAD/CAM Software Update Adds Features, Functions

CAM-Tool version 19.1 from CGS North America updates the software program to include more features and functions for high-accuracy mold and die machining.

-

How to Generate the Ideal Tool Path for High-Level Accuracy and Finish

When a mold builder can’t compromise part accuracy and surface finish, CAM software with specialized programming strategies is essential.

-

IMTS 2022 in a Flash

With this still being the month of IMTS, I thought I’d highlight some of the technology mold builders have expressed growing interest in and are actively investigating, and what was on the show floor.

-

IMTS 2022: From Precision Products & Professionals to Podcasts & Parties

Four years since the last IMTS and this 2022 event served up plenty of product line expansions, technology enhancements, candid conversations about business challenges and deep discussions about using technology and training to stay competitive.

-

Surface-Based CAM System for High-Accuracy 3D Machining

CAM-Tool by CGS North America is backed by a variety of toolpath options and a comprehensive support team. The company will be exhibiting at IMTS 2022.

-

Amerimold 2021 Post-Show Flashback: Engineer

More moldmaker exhibitor highlights from Amerimold 2021, from a P20-modified mold steel grade and free-machining stainless steel mold base material, to an automated knowledge-based mold design solution.

-

A Fresh and Seasoned Perspective on Amerimold

What features stood out? How is the industry evolving? What did you take away from the event? How did it compare to being remote for so long? MMT’s editors took the opportunity to reflect on the mold manufacturing trade show back in September.

-

CAD/CAM System Competent Point Rearrangement Function for Optimal Surface Finish

Known for its high-accuracy, surface-based CAM calculation engine, CAM-Tool’s new function provides smoother toolpath cutting points and machine template customization.

-

Advancing the Mold with Amerimold 2021 Education Sessions

With an expanded three day schedule, more free educational sessions are being offered than ever before, including a range of sessions from Amerimold exhibitors.

-

CGS North America to Launch CAM-Tool Version 17

CGS North America to demonstrate new toolpath boundary within CAM-Tool’s Common Settings at Amerimold 2021.

-

CAM System Eliminates Overtravel Issues, Saves Programming Time

CAM-tool by CGS North America provides mold and die manufactures a wide range of modeling capabilities and will be releasing additional improvements for increased optimization.

-

Software Decreases Movement for Smoother, More Accurate Tool Paths

Cam-Tool by CGS North America, Inc. has improved its simultaneous five-axis conversion (auto) function. The process has been updated to decrease movement of extra axis when unnecessary.

-

Tech Trends: Suitable Software

CAM software programs and updates from Autodesk, Inc., CAM-TOOL by CGS North America, Inc., and CGTech provide a range of features, including independent operation, reduced cycle times and easier machining programming, simulation and verification.

-

Unique Five-Axis CAM Programming Helps Moldmaker Meet Strict Specs

When it comes to hard milling and tough surface finish requirements, X-Cell Tool finds one CAM software’s approach answers the call for perfection.

-

Simultaneous Five-Axis Conversion Process Decreases Unnecessary Movements

CGS North America releases version 15.1 of its CAM-Tool software.

-

Tech Trends: Maximize Moldmaking Processes

Check out these latest products from Unisig, GF Machining Solutions, Mitutoyo America Corporation, CGS North America and Volume Graphics that can help you maximize your moldmaking processes!

-

Makino Continues to Raise the Bar on Machining Technologies

Packed with information to help attendees advance moldmaking, and more, Makino’s Technology Expo shows the company’s commitment to its customers’ successes.

-

Amerimold 2019: Software Solutions for Moldmaking

Looking for software options that are developed for moldmaking? Amerimold had plenty in store for attendees and we bring you some highlights here.

-

2019 Technology Review: Software

MoldMaking Technology’s July 2019 Technology Review and Sourcing Guide offers some of the latest highlighted products and services from supplier companies from a variety of categories, including software.

-

2019 Leadtime Leader Award Winner: X-Cell Tool and Mold Inc.–The Continuous Drive for Perfection

Continued investment in new technologies and automation has enabled this moldmaker to maintain shorter lead times no matter how large or complex the mold build.

-

Software Update Ensures High-Quality Finishes

CGS North America releases an updated version of CAM-TOOL, V15.1, the CAD/CAM system corresponding to the five-axis machining center for molds and dies.

-

Collaboration, Flexibility, Speed and More at IMTS 2018

Attendees walked the miles of aisles to find that IMTS 2018 delivered it all and so much more.

-

IMTS 2018: Process,Technology and Service Advancements

Advancements in automation and digital manufacturing took center stage during IMTS last week, but developments in additive manufacturing, cutter technology, machining solutions, simulation software, EDM, laser technology and customer service were other hot items.

-

2018 Technology Review and Sourcing Guide: Software

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including software.

-

CAD/CAM Software Improves Accuracy with Version Upgrade

CGS North America introduces the latest version of its CAM-Tool software at Amerimold 2018.

-

Software Technology Is More Versatile, Efficient and Simplified

Software suppliers are working diligently to provide moldmakers with relevant but easy-to-use solutions that speed processes and lower costs.

-

Throwback Thursday: Software Advances Push Limits of Speed and Quality

This throwback article provides interesting perspectives on software for moldmaking while also illustrating how fast software technology moves today.

-

Amerimold 2017: Multitudes of Metalworking Materials and Machines

Amerimold proved once again that it is THE event for moldmaking.

-

Stepping Up to the Challenge

This roughing strategy helps maximize metal removal rates and reduce roughing cycle times.

-

Technology Showcase: Case Studies

Here’s a Technology Showcase review of past case studies that you may have seen, but that may also be worth another look.

-

Reducing Risk in Lights-Out Machining

Surface-based CAM software can increase accuracy and make unattended machining a possibility for shops that have avoided it in the past.

-

Make a Case for Your Favorite Product in MMT

Like Sherlock Holmes, I’m looking for clues. The right clues will lead me to uncovering the facts about products that have significantly impacted the operations of moldmakers and molders. So readers, consider this a call for case studies!

-

High Accuracy and Efficiency CAM System Speeds Mold Building

The ability to machine smaller details into molds has reduced or often even eliminated the need for secondary surface finish operations.

-

Software Advances Push Limits of Speed and Quality

Software for moldmaking continues to evolve as sophisticated features and capabilities are introduced, enabling mold manufacturers to produce the highest quality work in the most compressed leadtimes to date.

-

Unique Mold Challenge Showcases Moldmaker as Customer Consultant

Ultimately, the Roembke Mfg. mold was a single-drop cold deck with a standard LSR valve gate design featuring side injection versus back injection for the plastic.

-

Case Study: Software

CAM Package Streamlines Five-Axis Machining for Electronics/Medical Moldmaker

-

Cutting Tool/Software Providers Combine Efforts to Maximize Productivity

Collaboration amongst suppliers to be expert solutions providers is key to a moldmaker’s ability to maximize production throughout their entire manufacturing process—increasing efficiency and productivity.

-

CAM for Hard Milling

A brief overview of some of the CAM requirements, challenges and strategies for successful hard milling.

-

Packaging Molds Go High-Tech to Improve Productivity and Economy

The ability to design and build innovative molds for advanced processing needs is key to being competitive and profitable in a low-margin market.

-

A.J. Tool Co. Inc.: Niche Moldmaking Meets High Expectations

Top-notch customer service combined with loyal, hardworking employees that work together toward continuous improvement land this moldmaker the MoldMaking Technology 2006 Leadtime Leader Award: Small Shop.

-

Machining Molds with Negative Stock Shutoffs

Negative stock shutoff can help you make better molds in less time. Here is a clear definition and description of the process. While the concept is fairly simple, the implementation can be challenging.

-

Small Shop Survival: Changing Your Approach to Mold Building

Seeking out true value-added service from suppliers and a modest investment in new technology coupled with existing, more traditional equipment is a more sensible approach to moldmaking for the small shop.