Make a Case for Your Favorite Product in MMT

Like Sherlock Holmes, I’m looking for clues. The right clues will lead me to uncovering the facts about products that have significantly impacted the operations of moldmakers and molders. So readers, consider this a call for case studies!

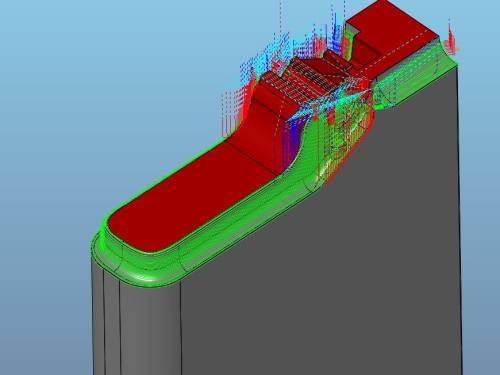

This image comes from our February case study about how CG CAM-Tool positively impacted a moldmaker's accuracy and efficiency when creating tool paths.

Like Sherlock Holmes, I’m looking for clues. The right clues will lead me to uncovering the facts about products that have significantly impacted the operations of moldmakers and molders. So readers, consider this a call for case studies!

By saying “significantly impacted” I mean, of course, in a positive way. Moldmakers, do you have a product, be it software, machine, maintenance tool or any number of auxiliaries that have really helped you to streamline operations, improve quality and delivery or cut costs? Perhaps there is a product that’s done all of these things. I want to hear about it.

Molders, I’m interested in hearing from you as well. What key piece of machinery or quality control device has upped your game? Where have you seen notable improvement due to a monitoring or measurement and inspection product? Are you seeing more perfect parts being manufactured in your facility because a certain product has offered benefits that are working for you?

I can’t leave out suppliers. They are the crux of a case study focused article, and without them moldmakers and molders would not have their success stories. So suppliers, do you have a good customer who might be willing to share a data-supported story that involves your product or service? Hook me up!

Case studies like the one I wrote for our February issue aren’t about giving company secrets away. Realistically, it’s a sharing of knowledge, lessons learned, useful tools or techniques and successes that all came through the use of a product. It’s almost like presenting a webinar or conference session where you share best practices, but this is published in MoldMaking Technology.

Keep in mind that you don’t have to be a writer. That’s what I’m here for. By using a basic questionnaire to lay the groundwork, and via a phone interview, I’ll gather the right clues to help me mold your story into an informational case study. It’s a great partnership and portrays the companies and products in a positive light. Oh, and a few photos and even a video that can be used to support the story are appreciated.

So, I’ve got my sleuthing gear ready—who will be the first to email me with a clue? I look forward to discovering ways in which products are helping moldmakers and molders find success.

Related Content

-

How to Determine the Proper Vent Depth

Vent depth is critical to optimizing mold performance, so here is one approach to finding that elusive right number.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.