CAM System Eliminates Overtravel Issues, Saves Programming Time

CAM-tool by CGS North America provides mold and die manufactures a wide range of modeling capabilities and will be releasing additional improvements for increased optimization.

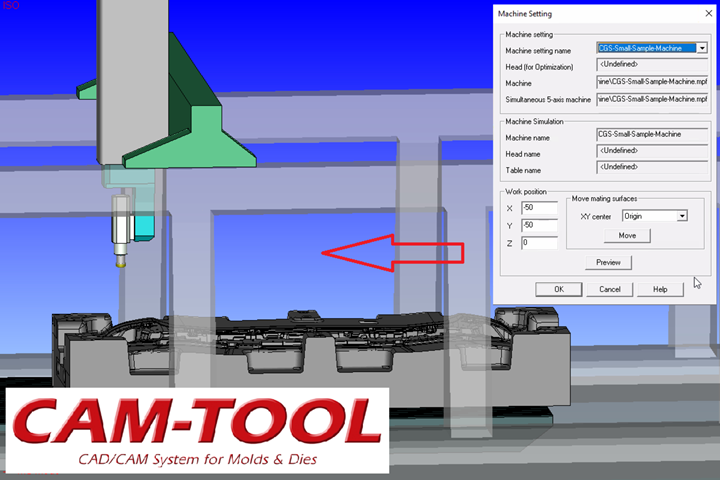

Photo Credit: CGS North America (Cam-tool).

CAM-Tool by CGS North America, is a high-end CAD/CAM system that provides mold and die manufactures a wide range of modeling capabilities not found in “high-end” programming systems. For example, CGS North America notes that once a user’s data has been prepared, the calculation of the NC toolpath is completed by simply defining one’s machining strategy and cutting tools. CAM-Tool is said to do the rest, making sure the tool only goes where necessary to remove material using its optimization capabilities. CAM-Tool creates toolpath based on surfaces, and not a mesh, improving finish quality.

According to the company, CAM-Tool will be releasing version 17 this summer 2021. Some of the big improvements include added automation in the Tree View and the ability to preview and move a job on the machine before starting to program. This allows the programmer to ensure there will be no overtravel issues once the job is set up and avoids wasted time moving jobs. Overtravel checks have also been built into the optimization of each tool path, eliminating the need to open the machine simulator. This is said to save programmers time while still ensuring the tool path safety CAM-Tool is known for.

Related Content

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

.jpg;maxWidth=300;quality=90)