TBT: Integrating Electrode Production

Many companies have an amazing setup in their shops and the machines are running day and night. But one thing still stands out for even the most advanced shops: how slow the EDM process can be.

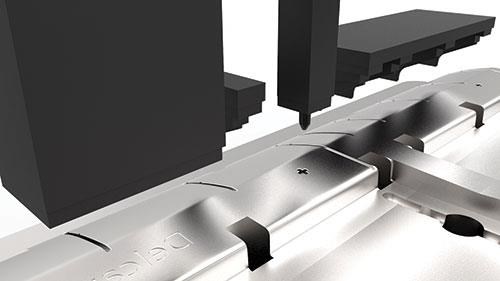

An integrated system for the design, machining and inspection of electrodes.

During my time working in this industry I’ve toured many mold shops to learn about how they manage design and production. Many companies have an amazing setup in their shops and the machines are running day and night. But one thing still stands out for even the most advanced shops: how slow the EDM process can be.

Many of the more advanced moldmakers have purchased very fast, five-axis CNC machines that can provide very nice surface finishes, even in tight spots on the tooling, but no one can deny the need for EDM on many projects even despite the high-end CNC’s capabilities. So how do we speed the design, machining and inspection of electrodes so that it’s more turnkey and doesn’t hold up other processes?

Check out this week’s Throwback Thursday feature, titled Integrating Electrode Production, which was published in MMT’s October 2013 issue. In it, a strategy for integrating EDM more efficiently into the overall manufacturing process using CAD/CAM is discussed. I think it’s as relevant as ever and can make sense for any moldmaking company. There’s even a video that shows you how one shop, our 2015 Leadtime Leader Cavalier Tool, is streamlining the process this way. Check it all out here.

Speaking of Leadtime Leaders – We’re putting the call out for entries now. You can’t win it if you don’t get in it! Enter by completing the application here.

Related Content

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.