CAE Services Corporation

280 Belleview Ln.

Batavia, IL 60510 US

630-761-9898

mark@caeservices.com

caeservices.com

IS THIS YOUR COMPANY?

As Seen On MoldMaking Technology

CAE Services Corporation Supplies the Following Products

- CAE (Computer Aided Engineering)

- Consulting Services

- Injection Molds

- Mold Flow and Simulation Software

- Testing/Analysis Services

Editorial, News, and Products

-

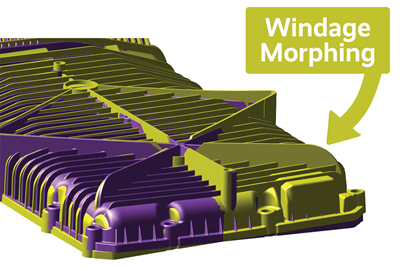

How to Fix Predicted Warpage Before It Happens with Windage and CAD Model Morphing

Applying windage and model-morphing techniques saved toolmaker/molder Sturgis Molded Products the time, cost, headaches of multiple part/mold design iteration loops, cumbersome cooling fixtures, and long molding cycles.

-

NexGenSolutions, CAE Services Collaborate on Molding Simulation

Firms join forces to provide solutions and support for Moldflow users.

-

PTXPO Preview 2023: Upcoming Software/Simulation Services, Training and Marketing Solutions

This latest installment of PTXPO snapshots feature companies in and around the Moldmaking Pavilion powered by Amerimold that provide industry solutions in software, simulation, training and marketing.

-

Check Out MoldMaking Technology's Most-Viewed August Content

Here is a list of the most-viewed August content based on analytics – from high-speed machining, 3D printing and simulation to a moldmaking scholarship prize, standardization and circle segment milling. Take a look at what you may have missed.

-

Quickly Troubleshoot New Molding Defect with Moldfilling Software

SyBridge Technologies analyst compares original, new Moldflow process simulation results, solves molding defect without tool needing to be taken out of production.

-

VIDEO: Molding Simulation Brings the Mold Builder and Molder Together

Mark Solberg, Executive VP of CAE Services and Jason Bonanno, VP – New Business Development of CAE, discuss CAE’s Moldflow analysis services. Learn how to know when your shop needs to outsource or invest in software and the mold builder’s role in using mold analysis software.

-

“Molds Make a Difference” at the Plastics Technology Expo

That was the sentiment of every person who came up to the MoldMaking Technology booth during last week’s Plastics Technology Expo to grab their giveaway “Molds Make” t-shirt after working the aisles seeking technology and process solutions and making new business connections.

-

A Fresh and Seasoned Perspective on Amerimold

What features stood out? How is the industry evolving? What did you take away from the event? How did it compare to being remote for so long? MMT’s editors took the opportunity to reflect on the mold manufacturing trade show back in September.

-

Amerimold 2021 Post-Show Flashback: Maintain

Products, equipment and services for surface treatment, mold maintenance and repair were some of the more popular items on the Amerimold show floor this year.

-

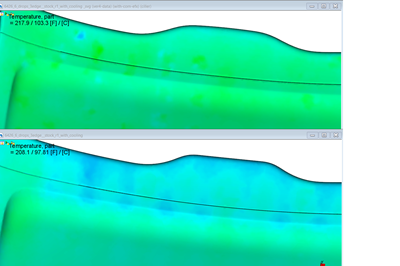

Moldflow Analysis Software Takes the Guesswork Out of Kentucky Windage

CAE Services’ Moldflow windage analysis and morphing capabilities determines and delivers proper windage shape, saving rework and expense.

-

CAE Services Solves Complex Part Design, Tooling Issues Via Analysis Services

CAE Services, a global provider of Moldflow analysis services, will be exhibiting at Amerimold 2021.

-

WEBINAR: Wake-Up Call to the Benefits of Simulation for Warpage and Windage

The impressive response of manufacturing to the urgent medical product development and delivery challenges COVID-19 presented was due in part to the use of simulation software. This free webinar takes attendees through a real-world example that used mold flow simulation to identify Kentucky Windage as the cause of warpage issues on a much-needed medical device.

-

WEBINAR: How Do You Reduce Risk in Plastic Part Design and Manufacturing?

The answer is simulation, of course. In this free on-demand webinar, you will learn how to use upfront simulation to reduce manufacturing risk, design of experiments to make more informed decisions and simulation input to speed machine start up.

-

Moldflow Analysis Solves Part Design Concerns

CAE Services uses Moldflow to analyze, identify and solve part design or warpage related concerns before cutting steel.

-

CAE Services Launches Monthly Webinar Series

CAE Services introduces Ask the Moldflow Experts, a new monthly webinar series developed to address Moldflow-related questions from an experienced, credible and trustworthy resource.

-

Noteworthy News: Working Together

Businesses like Emuge Corp., MC Machinery Systems, Inc., DMG MORI and more have made partnerships in order to benefit the moldmaking community.

-

Noteworthy News: Helping Hands

As we hear so often in moldmaking, building relationships is one of the keys to a business’s success. So, here’s a look at some recent new releases detailing partnerships within the industry!

-

Engineering Services Provider Offers Cost-Effective Approach to Solving Warpage

CAE Services Corp. offers the analysis capabilities to predict windage adjustments to the shape of the mold prior to cutting steel.

-

Amerimold 2019 Update: What You Should Know about Getting Venting Right

This presentation will review several ways to get your venting right, including guidelines for designing and machining vents to optimize venting capacity, proper vent amount, location, width and depth, using a vacuum/blowback venting system and modifying the tool for vacuum venting, using and designing with self-venting mold material, and installing the most efficient mold components, such as vacuum vent blocks and venting valves.

-

2018 Technology Review and Sourcing Guide: Inspection/Measurement

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including inspection/measurement.

-

2018 Technology Review and Sourcing Guide: Software

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including software.

-

Software Technology Is More Versatile, Efficient and Simplified

Software suppliers are working diligently to provide moldmakers with relevant but easy-to-use solutions that speed processes and lower costs.

-

Throwback Thursday: Software Advances Push Limits of Speed and Quality

This throwback article provides interesting perspectives on software for moldmaking while also illustrating how fast software technology moves today.

-

Technology Tuesday: Preparing for NPE with Plastics Review

This slideshow has you covered in plastics review with discussion on common plastics problems like sticking and warping. It includes pieces on software analysis for plastic parts, and it even includes a piece on making the most out of used plastic.

-

Throwback Thursday: The Science of Simulation

From evaluating part, mold and process designs and improving mold cooling to reducing plastic part warpage and determining the best gate locations, simulation plays a key role. MMT has provided a series of articles on just these topics, which I thought I'd share.

-

What Do You Really Know about Mold Cooling?

Do you ever ask yourself why cycle time matters? Although the level of impact may vary across the supply chain, one thing is certain: reducing cycle times can lead to hidden cost savings. And with cooling and recovery making up more than 80 percent of the injection molding cycle, it is the perfect place for improvement to help reduce cycle times. Listen to this webinar to learn how to achieve optimal cooling through analysis.

-

Cooling Is a Hot Topic

Mold cooling is one of the most important elements to mold productivity because it can greatly impact cycle time and part quality, which of course affect the bottom line ... your profitability. Check out these two upcoming webinars that tackle a variety of mold cooling challenges and solutions.

-

What is Your Plastic Pain Point?

Many will agree that one of the most frustrating aspects of plastic injection molding is warping. With that in mind MMT joined a Moldflow engineering services provider in a webinar to show how the manufacture of plastic parts affects their final shape. Take a look at three key questions asked during the discussion, and then view the recording.

-

Do You Want to Know Why Plastic Parts Warp?

I have worked with Tim Lankisch, director of engineering at CAE Services on numerous technical articles and educational videos in MMT focused on the value of simulation. Yesterday Tim came off the printed page and went live in an MMT webinar that analyzed why plastic parts warp. View archived recording now.

-

Designing Flow Leaders and Restrictors

Use simulation to control flow in your injection molds.

-

The Kentucky Windage Solution in Simulation Reduces Warpage

Using simulation to bias your mold and reduce warpage.

-

Get the Red Out

Using simulation to predict high-conductivity insert performance.

-

Are You a Control Freak?

Using simulation to determine the right valve gate sequence.

-

Circuiting Done Right

Using cooling simulation to circuit your cooling lines properly.

-

Software Advances Push Limits of Speed and Quality

Software for moldmaking continues to evolve as sophisticated features and capabilities are introduced, enabling mold manufacturers to produce the highest quality work in the most compressed leadtimes to date.

-

Using Simulation to Locate and Size Gates

Considerations and trade-offs when determining proper gate locations with simulation, which helps all stakeholders make a sound decision based on the priorities of the project.

-

Moldmaker Uses a Solution-Based Approach To Mold Flow Analysis

MoldFlow consulting firm assists mold shop as it approached a complex molding program for its customer, Cessna Aircraft Company.

-

Saving Money with Gas-Assist Analysis

How to use simulation results to save money.

-

ASH Industries Relies on CAE Services for Production Advances

CAE simulations and Mold-Vac units help bolster quality and customer satisfaction.