Cooling Is a Hot Topic

Mold cooling is one of the most important elements to mold productivity because it can greatly impact cycle time and part quality, which of course affect the bottom line ... your profitability. Check out these two upcoming webinars that tackle a variety of mold cooling challenges and solutions.

Mold cooling is one of the most important elements to mold productivity because it can greatly impact cycle time and part quality, which of course affect the bottom line ... your profitability. MMT has continually covered mold cooling challenges and solutions and next month we are featuring two webinars that tackle mold cooling issues.

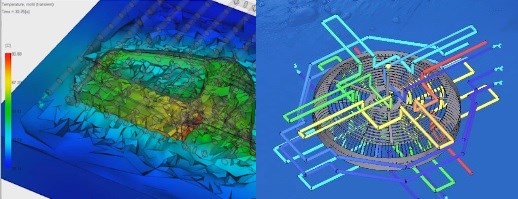

First up, on April 19, 2016 at 2:00p.m. EST CAE Services will be covering cycle time, cooling and injection molding since 80 percent of that molding process involves cooling. The webinar will show how cooling analysis can accurately simulate any number of cooling designs to optimize part quality and reduce cycle times. Then on April 27th at 10:00a.m. EST Autodesk will review cooling design rules by presenting case studies on how to optimize cooling with additive manufacturing and conformal cooling. Click on the links to register for free today.

You might also want to check out these related videos: the first explains how mold cooling is not just about the placement of the cooling lines, but also getting the circuiting right, and the second video demonstrates parallel processing, which predicts transient cooling for the injection mold as well as the cooling channels.

Related Content

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.