WEBINAR: How Do You Reduce Risk in Plastic Part Design and Manufacturing?

The answer is simulation, of course. In this free on-demand webinar, you will learn how to use upfront simulation to reduce manufacturing risk, design of experiments to make more informed decisions and simulation input to speed machine start up.

When audience members were asked to share the frequency at which their companies make changes to part and/or mold design to produce acceptable parts, the majority answered: 1-2 or 3-4 iterations. This result emphasizes the importance of learning how to reduce risk in manufacturing.

Dr. Matt Jaworski, a senior subject matter expert for Autodesk’s Moldflow Simulation Team shares his insights on the value of mold flow simulation. He starts off with key bullet points about:

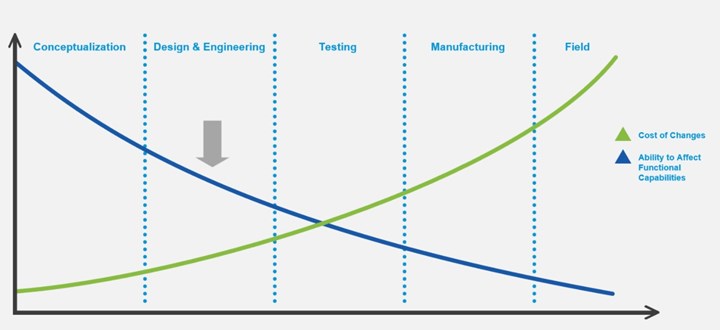

- The cost of change can be decreased with better decision making early on

- The design phase offers a unique area of time during which we can impact the end product at a much lower cost and why simulation is so important.

- Why do all companies NOT do simulation? Common struggles of putting simulation in the hands of designers:

- Change is hard, and a shift in established processes and workflows is necessary

- Need upper-level buy-in

- Takes experience

- A lack of time and details does not match the required accuracy and time

- Outsource this part of the process which can create extra iteration costs

He also answers questions about the role the simulation plays upfront, how cloud solving works (its security and cost concerns), how design of experiments and existing tools to handle statistics can be used with mold flow simulation software, ways to implement a scorecard, how a part iteration in the concept stage is not the same as a part change in the mold build or after build phase, the pros and cons of simply modeling cooling channels in Moldflow versus bringing the mold design inclusive of actual planned cooling into the analysis, and the training required.

Other key takeaways include:

- Upfront simulation workflows and design of experiments can be useful tools to reduce risk.

- The power of the design of experiments lies in the ability to see the sensitivity of user-defined variables and quality criteria, as well as the use of this information later in the process.

- With simulation you can evaluate part design decisions, optimize manufacturability, eliminate potential molding issues and solve part tolerance issues.

- Simulation expands overall team knowledge of how plastics and molds work for design, mold builder, and plastics engineers.

- Link simulation with the injection molding machine to not let simulation data go to waste.

- Seek knowledgeable experience and a guided implementation plan.

Related Content

-

MMT Chats: Westfall Technik Talks Runnerless Micro Molds and More

Westfall Technik sits down with MMT Editorial Director Christina Fuges to discuss their new micro hot runner technology, the closeness of the moldmaking community and the importance of integration. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

MMT Chats: California Mold Builder Discusses the Difficulties with Silicone Molding and the Power of the Magic 8 Ball

MoldMaking Technology Editorial Director Christina Fuges sits down with M.R. Mold President and Owner, Rick Finnie, to discuss how he began his moldmaking career, M.R. Mold's LSR Education, and the struggles of working with silicone. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

Unique Mold Design Apprenticeship Using Untapped Resources

To help fill his mold design skills gap, Jeff Mertz of Anova Innovations, is focused on high schools and underprivileged school districts, a school that has lower graduation and college entrance rates. The goal is a student-run enterprise.

.jpg;maxWidth=300;quality=90)