Photo credits, clockwise from top left: Simcon, Beaumont Technologies, Kruse and Creative Technology

The Plastics Technology Expo (PTXPO), taking place this year March 28-30, 2023, at the Donald E. Stephens Convention Center in Rosemont, Illinois, brings partners across the supply chain together. Take a moment to familiarize yourself with the exhibitors that you can expect to meet in the Moldmaking Pavilion, powered by Amerimold.

Below is a snapshot of each exhibitor most relevant to moldmaking in the areas of software, simulation services, training and marketing*. Each profile shares details important to the company’s business and innovations, including why and what they are exhibiting at PTXPO in or around the MoldMaking Pavilion. Booths located outside this pavilion are denoted by two asterisks along with information on where to find them.

Use promo code MMT23 and register today for your FREE exhibit hall pass, and we’ll see YOU in Chicago!

*This exhibitor list is subject to change. Current as of 2/6/23

Get to Know Cimatron

Moldmaking is important to Cimatron because it is the number-one focus of the team and product.

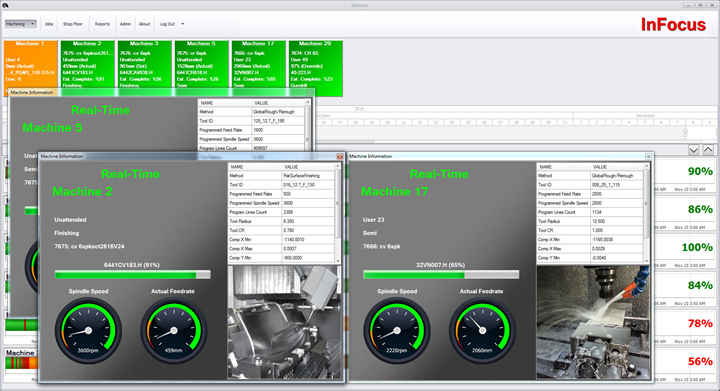

Part of the Sandvik Group, Cimatron provides toolmakers with an end-to-end solution for designing and manufacturing tools including molds, dies and electrodes, as well as programming any CNC and EDM machine for molds, dies, plates and discrete manufacturing.

Cimatron is an integrated CAD/CAM system for the design and manufacture of plastic injection molds and sheet metal stamping dies, as well as programming 2D to five-axis milling CNC machines. Created with the moldmaker in mind, the system enables automatic generation of intelligent conformal cooling channels that cling to the walls of the part that requires cooling for faster cycle times, better part quality and a more efficient cooling process. Users can control and modify the automated results or design their own channel quickly and easily — turning hours of design work into minutes. While Cimatron is at its most powerful when used as a fully integrated system, it also provides standalone solutions for faster quoting, tool design, electrode creation and NC programming.

Customer testimonials about improving part quality, reducing scrapped parts and sink mark-affected areas, shortening cooling process and cycle time and cutting the total manufacturing costs are well-documented.

Photo Credit: Cimatron

Cimatron is celebrating its 40th birthday. The company will be presenting version 16 of Cimatron, a leading CAD/CAM software for the mold and die industry. Visit Booth 1434 to learn about this latest release delivering many new features, including a clean new user interface and increased automation for faster mold design, electrode creation and NC programming. Explore other advancements for toolmakers such as powerful functionality for die addendum surfaces, mesh manipulation and drafting detailing. The Cimatron team will be demoing how to increase productivity, competitiveness and profitability with a wide range of dedicated, applicative tools.

Get to Know SIGMASOFT® Virtual Molding

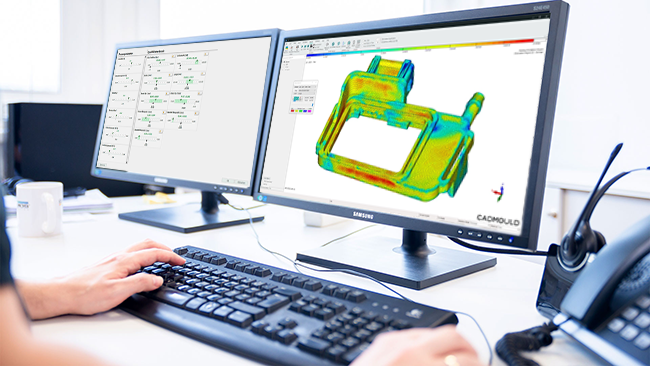

Quality manufacturing depends on the ability of the mold to produce the desired part. SIGMASOFT® is the ideal tool to evaluate the mold design at any stage to ensure quality parts.

Photo Credit: Sigmasoft

The company has developed a comprehensive software that enables users to analyze complex mold designs in few steps, as well as consider the impact of cycling the mold multiple times until it reaches a balanced temperature. Considering the complete mold, process parameters, machine specs and material properties all at once is key to capturing the true behavior of the part.

SIGMASOFT® has also considered the benchmark in injection molding simulation accuracy, and are well known for its expert, always-accessible support.

In addition to state-of-the-art technology, SIGMASOFT® features knowledgeable staff in all areas of plastic processing, with more than 50 years combined of direct floor experience in the manufacturing of thermoplastics, elastomers, LSRs and thermosets. Attendees can visit Booth 920 to learn more.

Get to Know TopSolid USA

TopSolid understands better than most that moldmaking is at the heart of manufacturing. Understanding the importance of the market and the requirements for CAD/CAM technologies, TopSolid’s Integrated Digital Factory has been developed from the ground up specifically to ensure the fastest and most accurate manufacturing process possible.

The Integrated Digital Factory is a solution for manufacturing written by manufacturers that enables users to complete every step of the mold manufacturing process within one tightly integrated solution from start to finish. This includes designing or the modification of plastic parts, core and cavity creation including sub inserts and moving components, down to the full 3D mold design (including plastic flow analysis) and then onto documenting the design with TopSolid’s drafting environment. From there, a TopSolid customer can design their EDM electrodes, document and fully machine them. It’s even possible to machine in hard steel with TopSolid Cam. While all of this is occurring, TopSolid’s PDM core is managing all information and revisions in order to ensure all team members are always working to the very latest version of data.

Photo Credit: TopSolid USA

In Booth 1514, you can expect to see live, real-time demonstrations of the various aspects of the manufacturing process of molds. TopSolid experts are placed front and center to discuss and provide solutions on the spot, including Sales and Technical Director Bill Genc, a third-generation moldmaker who brings close to 30 years of international experience.

Genc will be at the show looking for a Midwest moldmaking company to partner with on a joint venture focused on updating the company’s digital process. The opportunity will enable joint marketing to promote both businesses within the moldmaking marketplace.

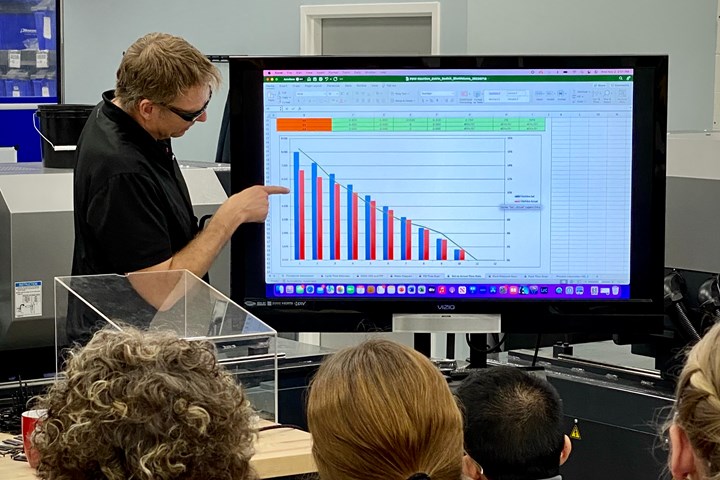

Get to Know Beaumont Technologies Inc.

Visit Booth 1009 to learn about Beaumont’s mission to help people improve their molds through training, technology and software simulation, and talk plastics with its team.

One of Beaumont’s many offerings is education and training. With this education, moldmakers can make better molds the first time around, resulting in more efficient processes and higher quality end products.

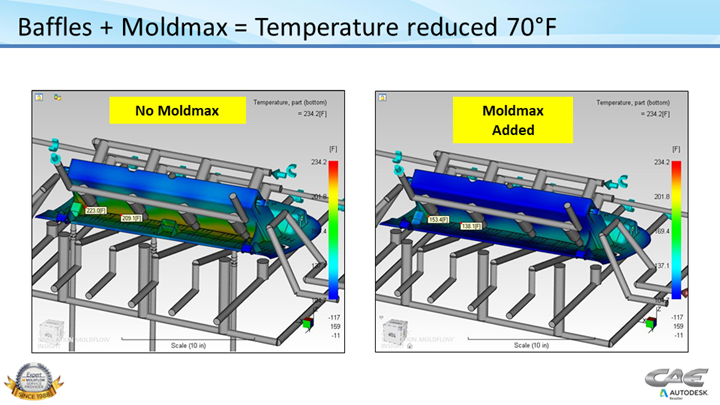

Outside of this realm of services, Beaumont also points to MeltFlipper, a patented runner design that influences plastic flow to promote uniform, high-quality molded products. The runner design helps an injection mold perform to its highest capability, enabling users to get the most out of their injection mold by controlling the variations that occur naturally during this process.

**Find Beaumont Technologies in the Injection & Blow Molding Pavilion.

Photo Credit: Beaumont Technologies Inc.

Get to Know Creative Technology Corp.

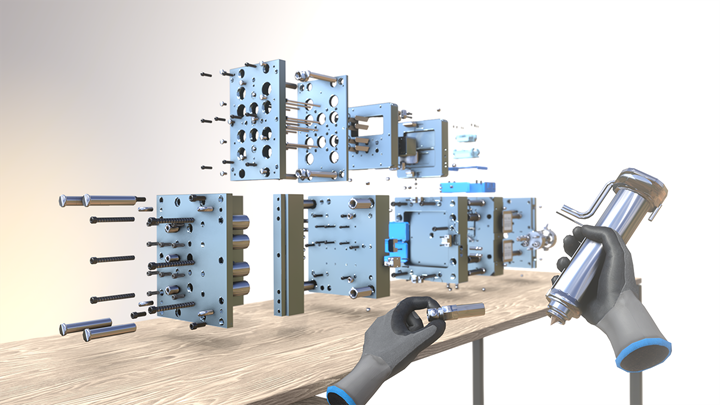

Visit Booth 1518 to meet the masters of marketing for manufacturers at Creative Technology Corp. With over 40 years of hands-on experience in the manufacturing marketplace, this team has the right equipment to highlight every aspect of a manufacturing business both inside and out — from the correct macro lens to capture a small medical part, to drones that fly seamlessly through a shop’s operation. They have the right tools to make your business stand out from the crowd. They consider it their job to get your shop noticed to attract talent and new customers.

Photo Credit: Creative Technology Corp.

The changes in the digital landscape and advancements in technology can help businesses connect with their audiences like never before. New relationships, partnerships and additional benefits exist that were not possible 25 years ago. Creative’s marketing expertise can give your shop a competitive advantage. They are here to help best leverage how you connect with others and how you’re viewed online.

Related Content

Unique Mold Design Apprenticeship Using Untapped Resources

To help fill his mold design skills gap, Jeff Mertz of Anova Innovations, is focused on high schools and underprivileged school districts, a school that has lower graduation and college entrance rates. The goal is a student-run enterprise.

Read MoreMMT Chats: The Science of Moldmaking, Part 2

In Part 2 of this two-part MMT Chat, Christina and Don continue their conversation by exploring lean manufacturing and tips on how to attract, train and retain the future workforce.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreMMT Chats: It’s Time to Play … The Moldmaker Card Game! Yes, a Game to Educate and Entertain

MoldMaking Technology Editorial Director Christina Fuges connects with Professor Steffen Ritter from Reutlingen University in Germany about the card game for moldmakers he developed to help promote and educate our next generation of moldmaking professionals in a fun way. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreRead Next

PTXPO Preview 2023: 3D Printing, Machining and Cutting Tools Technology and Services

The Moldmaking Pavilion powered by Amerimold is one of seven pavilions returning to PTXPO. Take a moment to familiarize yourself with those exhibitors that can fulfill your 3D printing and machining needs.

Read MorePTXPO Preview 2023: Mold Material/Mold Base Needs

At PTXPO 2023, the Moldmaking Pavilion returns, housing exhibitors ready to meet attendees' mold material and mold base challenges head on.

Read MorePTXPO 2023 Preview: Advancing the Mold With Featured Mold Component, Hot Runner Technology

There’s no doubt mold components and hot runners are important parts of the moldmaking industry. This preview gives mold buyers, mold builders and injection molders a look into PTXPO exhibitors displaying these technologies at the show.

Read More