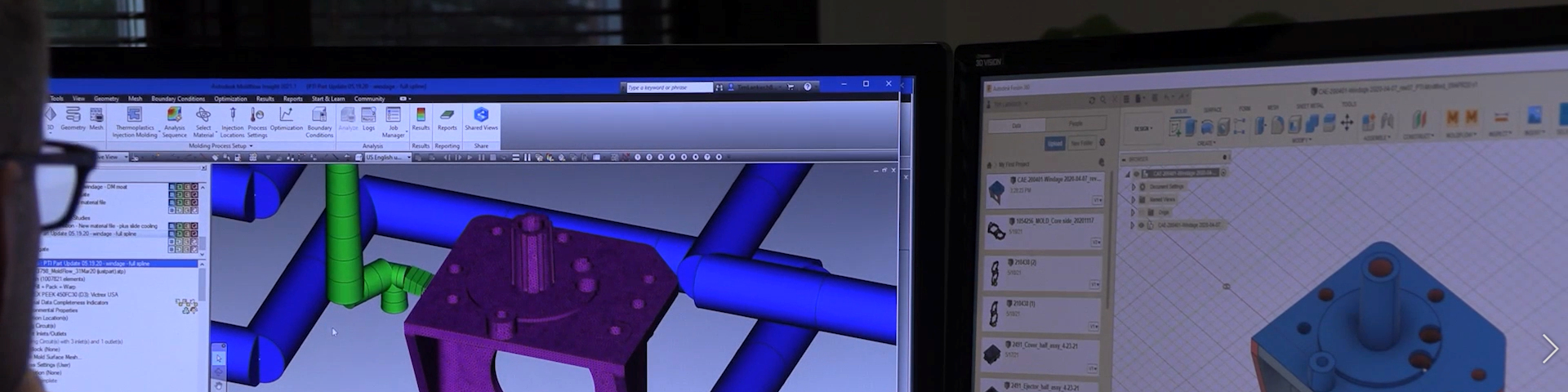

CAE discusses Moldflow simulation analysis, when a shop should outsource vs. invest in software and the mold builder’s role in mold analysis. They also go into detail about the importance of windage and morphing analysis as an accurate predictive tool when tolerance issues are a concern.

Chapters:

0:00 Introduction

3:08 When does a shop know whether to outsource or invest in software?

4:19 What is the mold builder's role in using the software?

7:00 The importance of windage and morphing analysis

9:55 Getting in the door

11:40 Why is cooling analysis valuable?

14:29 What is next for CAE?

For more video content from MMT, visit https://www.moldmakingtechnology.com/videos

Related Content

-

VIDEO: Standardization and the Future of Moldmaking

Progressive Components President Glenn Starkey discusses their focus on standardization and the future of moldmaking (it’s here to stay!).

-

Project Reveals Added Benefits of New P20 Grade Steel in Machinability, Cycle Time and No Stress Relief

MoldMaking Technology's Christina Fuges talks with General Motors' Shane Appel about a project testing a new P20 steel grade's dimensional stability.

-

MMT Chats: Westfall Technik Talks Runnerless Micro Molds and More

Westfall Technik sits down with MMT Editorial Director Christina Fuges to discuss their new micro hot runner technology, the closeness of the moldmaking community and the importance of integration. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.