Throwback Thursday: The Science of Simulation

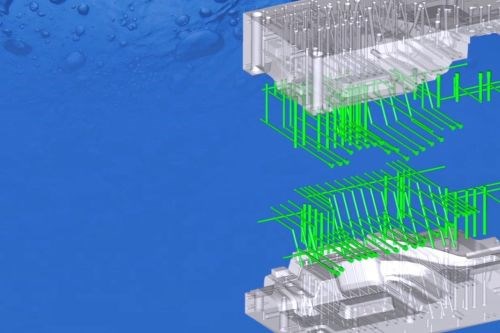

From evaluating part, mold and process designs and improving mold cooling to reducing plastic part warpage and determining the best gate locations, simulation plays a key role. MMT has provided a series of articles on just these topics, which I thought I'd share.

From evaluating part, mold and process designs and improving mold cooling to reducing plastic part warpage and determining the best gate locations, simulation plays a key role. MMT has provided a series of articles, videos, presentations and webinars on just these topics, which I thought I'd share.

Tim Lankisch of CAE Services, a provider of MoldFlow analysis services, has worked with MMT and Amerimold over the years to bring readers answers to many mold and molding questions through his expertise and knowledge of simulation technology solutions and strategies.

Tim has tackled using simulation to bias your mold and reduce warpage, using simulation to predict high-conductivity insert performance, considerations and trade-offs when determining proper gate locations with simulation, which helps all stakeholders make a sound decision based on the priorities of the project, using cooling simulation to circuit your cooling lines properly, using simulation to determine the right valve gate sequence, and using simulation to control flow in your injection molds.

He has also conducted webinars on why plastic parts warp and how to achieve optimal cooling through analysis.

Revisiting this content will be worth your while.

Related Content

-

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

.jpg;maxWidth=300;quality=90)