Build

The Data-Driven Operation

Manufacturing is a team effort involving suppliers, tool shops and customers throughout the world collaborating and sharing project data.

Read MoreChecklist for Long-Reach Toolholders

Moldmakers hoping to avoid problems such as chatter, poor tool life and molds that fail quality control muster need to consider a variety of factors when selecting a long-reach toolholder.

Read MoreInitial Pellet Contact is the Screw

Here’s what every moldmaker should know about an injection molding machine’s reciprocating screw, which is often misunderstood and applied to the process incorrectly.

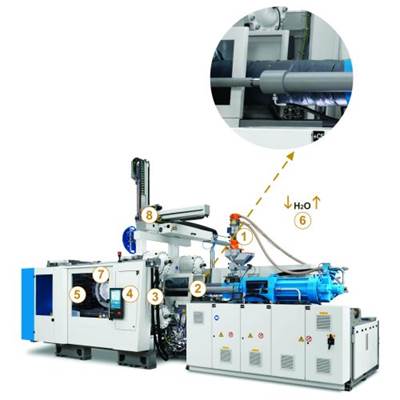

Read MoreNo More Cooling Required

Moldmakers and molders can increase mold uptime using today’s cooling-free valve gate actuators.

Read MoreMolding Very Small Threads and Undercuts Cleanly and Efficiently

New mold component technology helps engineers look differently at how they design small detailed parts.

Read MoreThe Will and the Way to Automate Mold Design

Persistence and the right technology enabled this automotive toolmaker to give programmers a head start on new projects and dramatically reduce calculation times.

Read MorePlastic Injection Molding Starts with the Pellet

This is the first article in a new series that will examine the injection molding process by breaking down the path a plastic pellet takes as it is transformed from Pellet 2 Part. It covers what every moldmaker should know about raw materials, including the fundamentals of viscosity curves, Melt Flow Index, Melt Flow Rate, shear and more.

Read MoreAdopting a Production Mindset

An HMC with a pallet changer and modular fixturing system has streamlined job change-overs at this Tier 2 automotive toolmaker.

Read MoreIntro to 3D Printing

With many moldmakers still unsure of the applications and value of 3D printing, I thought this news of a beginner 3D printing course that explores the technology's history, established applications, forward-looking trends and potential social and economic impacts would be interesting.

Read MoreUnconventional Strategies for Roughing

Arc of contact and average chip thickness are essential for optimizing rough-machining operations.

Read More