Build

On-Machine Texturing and Polishing

Laser technology highlighted at DMG MORI’s recent “Innovation Days” event enables users to texture molds still fixtured on the machining center. Plans are currently in the works to similarly automate polishing.

Read MoreDigital Ed. of MMT's May Additive Mfg. Supplement Ready

This month's edition features stories on how to push additive manufacturing to the next level with a commitment to customer service, education and training, as well as a look at one manufacturer's year-long journey with additive manufacturing.

Read MoreFive-Axis Myths

A look at the misinformation that prevents moldmakers from taking advantage of five-axis machining strategies to shorten total machining times.

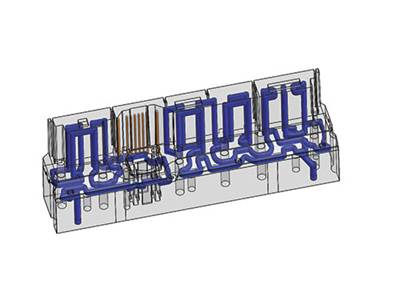

WatchFinancial Justification of Conformal Cooling

A ratio analysis helps illustrate the estimated effects of conformal cooling on profitability.

Read MoreConformal Cooling and Simulation in Real Mold Shops

Learn how innovative concepts in plastic manufacturing, such as conformal cooling and simulation technology are being used today in real mold shops.

WatchPlan Your Workholding for Improved Productivity

Choosing and organizing the right workholding can result in significantly improved machine efficiency, and it is essential for reaching any machine’s full potential.

Read MoreMetal Laser Sintering Hybrid Milling

Metal laser sintering hybrid milling combines metal powder 3D laser sintering with high speed milling finishing into one machining system.

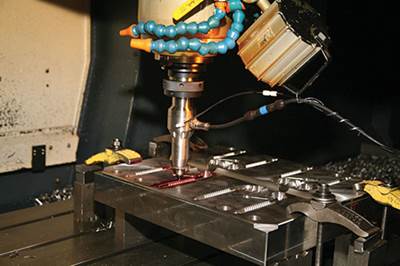

WatchRaising the Speed Limit for Smaller Cutters

An auxiliary electric spindle enables this shop to handle small features and intricate finishing work without investing in a new machining center.

Read MoreLaser Sintering and Milling Working Together

A hybrid manufacturing process offers mold builders an alternative method for making cores and cavities with time and cost savings and increased consistency.

Read More