Build

In Search of the Infinite Processing Window

Side-action preload can yield zero core movement during injection and help molders achieve a robust molding process.

Read MoreTooling Up for Challenging Cuts

To maximize quality and repeatability, you need the right cutting tools, especially in challenging applications. Here’s a guide for selecting tools for high-speed tool paths, tight areas, straight walls and graphite cutting.

WatchSmart Tooling

Combining cavity sensors with hot runner valve gate control yields new applications and greater process gains.

Read MoreHigh-Feed Face Mills Offer Speed, Versatility

Two new cutters not only improved machining speed at this mold manufacturer, but also showcased the potential of some high-feed tooling for heavier, deeper cuts.

Read MoreReduce Part Failure with Melt Delivery Science

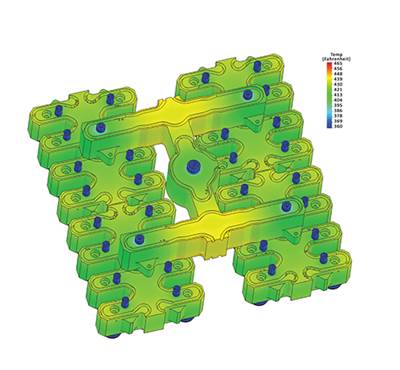

The best way to determine when naturally balanced, rheological managed and thermally balanced hot runner solutions are required as a single solution is to examine the science behind each approach.

Read MoreAdding Value with Robotics

A robot may not directly make the final part, but it can add value to the overall process, if its use is properly planned and executed.

Read MoreControlling the Melt Delivery System Heat Source

Understanding the heating systems along the melt delivery path is critical to setting up a robust process and properly diagnosing problems.

Read More"Smart" Technology

Although knowledge and expertise is just as important as ever, technology continues to advance toward almost thinking on its own.

Read MoreFlexibility, Low Overhead Seed Sustainable Success

Robotics, cross-training and efficient use of available floorspace help this shop adapt to the ebb and flow of business.

Read MoreHot Manifold Repair: What’s so Tough about it?

Maintaining a typical hot runner system takes mold maintenance skills to the next level.

Read More