The Data-Driven Operation

Manufacturing is a team effort involving suppliers, tool shops and customers throughout the world collaborating and sharing project data.

Manufacturing is a team effort involving suppliers, tool shops and customers throughout the world collaborating and sharing project data. There’s no such thing as a manufacturing project without data and information driving it from concept to completion. Data and files are clearly the lifeline that determines the success of a program.

Since the dawn of the industrial era, bulky file cabinets and paper manuals have been the preferred method for managing a manufacturing project. Sounds like a great plan if the only people you need to communicate with work in the same building as you.

Because manufacturing requires global collaboration and a vast supply chain, unexpected changes are common. Paper adds up, file cabinets only hold so much, and then your office and program are turned into a poorly operated disaster. Thankfully, computers have entered the workplace, but even they only provide a partial solution. Emails get deleted, FTP sites get cleared, USB sticks have limited access, and then, one week after an upload, engineering changes make that data irrelevant anyway, wasting time and money.

Fortunately, great strides have been made in data management, enabling companies to realize the value and savings that can be gained from efficiently managing and communicating data throughout the supply chain.

Data Management Options

Do the terms universal platform, digital sharing, cloud computing, web-based and 24/7 access sound familiar? If not, prepare yourself for the new era of data management, one in which your entire supply chain has fingertip access to the crucial data driving the operation.

Whether you are working with a mold builder in China, a manufacturer in Mexico or an OEM in the U.S., no communication is needed to access your project’s status. It’s as simple as logging in. This technology is much more than file-sharing and storage, as these platforms can often communicate with other software and provide a wide range of data tracking, reporting, security, sharing and management features. These features enable you to review your tryout information minutes after it occurs, view mold designs from your designer halfway across the world and ensure that you have the correct press specifications before the mold goes into production. This can be done from anywhere, at any time.

Here are key features to consider when reviewing your data management options:

Maintenance metrics. Common data management services only allow you to store your data. They aren’t tailored for the manufacturing industry and all of the complex data that powers it. However, software is being developed that enables customers to plug in or automatically download their manufacturing process and machine data. Referencing common maintenance practices and statistics, this software determines when maintenance should be performed or at least investigated, based on manufacturing formulas and program specifications.

Imagine your whole supply chain being capable of tracking and monitoring shot counts and cycle times, while uploading pictures of the asset to monitor important maintenance metrics. All of these features enable manufacturers to become operational powerhouses and reduce tool downtime on the plant floor.

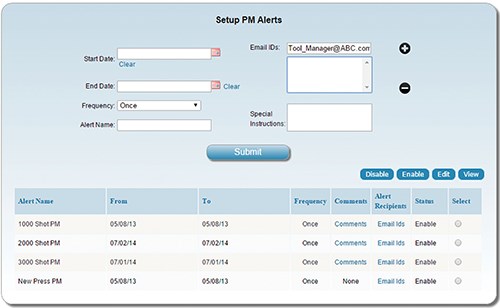

Alerts. Alerts are common for data management services, but in a system engineered for manufacturing, you can alert the entire supply chain through hands-free prompts and reminders about processes that require immediate attention.

The manufacturing industry is a fast-paced and ever-changing environment, which can lead to employees shuffling multiple duties. An automated alert system can advise personnel when it’s necessary to review maintenance issues or perform preventative maintenance. This reduces downtime and keeps programs running.

Locating assets is often another struggle for companies that have large global supply chains and customers. Automated updates based off of RFID and GPS technology are now being developed and released by data management companies. With the scan of a QR code or a GPS-recognized location change, alerts can be generated to update the people who need to know about an asset relocation.

Security. Keeping sensitive files safe and backed up is a major priority for users of data management services. Most management software only allows a user data access while he is logged into his own company network. Multi-million-dollar manufacturing programs with suppliers located globally cannot operate in that way. Sensitive information needs to be kept secure, but the ability to share that information instantly with the people who need it is necessary.

Advancements in secure data sharing platforms are allowing manufacturing companies to better collaborate on projects because they provide full access to the data they need, which yields better and faster business decisions.

Securing and protecting designs is a top priority for most manufacturing companies, as these designs are usually proprietary and confidential. New manufacturing-based data management systems allow the project to have one or multiple administrators who fully control access to information. They can monitor usage and logins for the entire supply chain, and password-protect files and data. A secure firewall and encrypted network, along with private user accounts, will keep your data safe and protected from those not permitted access.

Statistics, tracking and reporting. Having one centralized location for your entire supply chain to log performance statistics and monitor maintenance activity is essential in manufacturing, as some programs can last for decades, thereby making it difficult for users to remember what data to reference or where it is located. Data management services tailored for manufacturing provide customized reporting features that enable the users to study and review every aspect of a program.

Report all of your maintenance activity throughout the life of your program. Log issue descriptions, repair costs, time spent addressing specific problems, and, most importantly, problem and issue resolution. Reporting manufacturing performance allows you to reference a program’s history years down the road, showing you an asset’s depreciation or performance based on statistical data. Having a master log of your maintenance data is also critical for seeing the types of problems that occur so you can learn from them.

Mobile technology. Mobile apps now allow you to review and manage tooling projects from the palm of your hand. You can scan a QR code on a mold to review program details or access files. Having all of the pertinent data for your mold at your fingertips and the ability to instantly share that data globally throughout the supply chain can improve program communication and efficiency.

The potential for data management technology is virtually endless, as new ideas and features are regularly being developed to aid the management of manufacturing programs.

Related Content

How to Automate Process and Design

Moldmakers can improve their operations and stop wasting time by taking these six steps for process and design automation.

Read MoreDevelopments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

Read MoreFive-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read More5 Sinker EDM Advancements

Speed, machine design, software, artificial intelligence and automation help maximize sinker EDM productivity.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)