Build

Controlling Costs by Controlling Production

A process-driven manufacturing strategy and extensive data tracking have enabled this company to double down on the advantages of integrated toolmaking and molding capability.

Read MoreTool Up with Rapid Heat/Cool Technology

A rapid heating and cooling technique using pressurized water solves sink, weld line and discoloration problems.

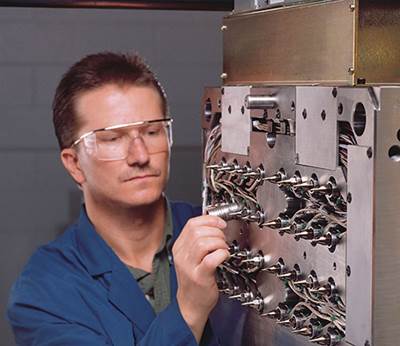

Read MoreHot Runner Running Efficiently?

Follow these tips to set up your system and keep it running smoothly.

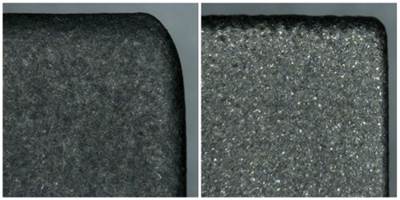

Read MoreGraphite vs. Copper Electrode Material for EDM Applications, Part 2

Test findings and a cost of ownership model help identify the monetary impact graphite and copper electrode materials have on manufacturing.

Read MoreOptimizing Common Roughing Technology

Keeping on top of the ever-advancing range of cutting technologies, edge geometry designs, materials and coatings is essential for achieving higher productivity, faster metal removal rates and more cost-effective machining processes.

Read MoreTruly Smart EDM

Think ease of use, ergonomics and expertise when empowering your operators with the right EDM.

WatchUser-Friendly EDM Control Technology

Wire EDM machines have taken ease-of-use to a new level, by being equipped with the next evolution of advanced machine control.

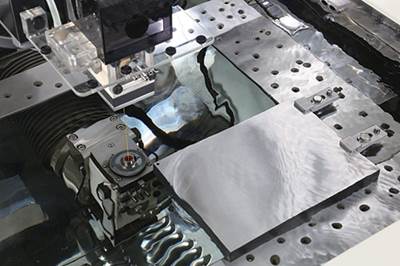

WatchBanking on Five-Axis Capability

Thanks to features that facilitate lights-out operation and an unusual, trunnion-type configuration, this shop expects its first five-axis machining center to keep it competitive for years to come.

Read MoreMMT at IMTS 2014

Last week at IMTS moldmakers were looking for technology to optimize their processes and to help them get a part off the machine with a bench-free finish. They want to save time and money without sacrificing quality. Two main areas of interest for moldmakers this year are the two As: automation and additive manufacturing.

Read MoreA View from the Top Reveals Craftsmanship from the Ground Up

From atop the YCM Americas Inc. double-deck booth visitors can sit and enjoy a beverage and snack while taking in the 14 machines on display this year that showcase the latest vertical, horizontal and five-axis machining technology as well as the company’s unique strengths in manufacturing machines from the ground up.

Read More