The Will and the Way to Automate Mold Design

Persistence and the right technology enabled this automotive toolmaker to give programmers a head start on new projects and dramatically reduce calculation times.

Unique Tool & Gauge is well-prepared for whatever the future may bring. So says Darcy King, president and CEO of the automotive toolmaker. Perhaps the most significant reason for that, he explains, is the breadth of the company’s customer base. Honda, Acura, Tesla, Toyota, GM, Nissan, Ford, Chrysler, BMW, Mercedes, Hyundai, Kia—all regularly source tooling manufactured at Unique’s 60,000-square-foot facility in Windsor, Ontario. This diversity was a major hedge against the 2008 recession, and King says he has no reason to believe it won’t provide a similar cushion if history repeats itself anytime soon.

That said, serving such a wide range of OEMs comes with its own set of challenges. Historically, one of the most significant has been the need to comply with complex mold design standards that vary with each and every customer. As a result, designers often spent hours poring over these standards and arranging components (screws, support pillars, manifolds and so forth) into the mold base accordingly. This painstaking task usually wasn’t difficult for the company’s skilled personnel, but it did take time. The longer the design phase, the longer the delay before actual production could begin.

Such tedium is now a thing of the past, King reports. Rather than starting from scratch, designers begin with virtually everything in place except for the cores, cavities and complex moving components that are directly involved in shaping the plastic. In essence, Unique Tool & Gauge has automated its design process. As a result, overall engineering time has been reduced by about half, a development that accounts for much of the company’s current prosperity, King says.

King gives much of the credit for automated programming to Cimatron CAD/CAM software, which offers the capability to capture customer-specific information in the system and reuse it as needed. However, mold manufacturing simply doesn’t lend itself to one-size-fits-all solutions. Although the software offered all the tools the company would need, including a mold-flow simulation package from a third-party developer, applying those tools to meet goals particular to Unique’s own operation required creativity, ingenuity and persistence. In short, the supplier provided the way forward, but the company itself had to provide the will to get there—that is, the will to forge ahead with a commitment to making maximum use of the resources at its disposal. Notably, this effort involved not just the software itself, but also the hardware on which it runs.

Standardizing Software

King says a refusal to settle for established practices is part of the family-owned company’s DNA. Founded in 1982, Unique Tool & Gauge specializes in concept-to-completion services for prototype and production molds, including multi-material, fabric overmolding, gas-assist and other specialized tooling. In addition to the sheer breadth of its customer base, he says the 90-employee company has set itself apart by helping to pioneer the use of aluminum tooling for production applications (see the link under "Editor's Picks" at the top right of your screen). Hari Sridharan, VP of engineering at Cimatron, can attest to the merits of Unique’s approach. “The philosophy of, ‘If it isn’t broke, don’t fix it’ is no way to progress in this industry, and Unique understands this,” he says. “Here is a company that’s always improving, always looking for better ways to do things.”

Sridharan would know. After all, his ongoing role in helping Unique leverage Cimatron for its own needs requires an intimate familiarity with the company’s operations. However, automated programming was still on the horizon when he first consulted with the toolmaker in 2009. Engineering Manager Joel Street, who would be among the leaders of the team responsible for that effort, explains that Unique initially sought to address a far more fundamental concern: the use of multiple software packages. In all, the company had been using two different CAD systems, one for wireframe modeling and one for surfacing, as well as a separate CAM system for creating tool paths.

Consolidating operations from three systems to one delivered all the benefits Unique expected. Moreover, Cimatron delivered those benefits almost immediately, Street says. Designers no longer had to sit and wait for files to translate from one package to another. Nor did they have to deal with geometry errors resulting from that translation. Different people could work on the same file simultaneously by “checking in” and “checking out” different sections of the mold to get the job done faster.

Smart Bases

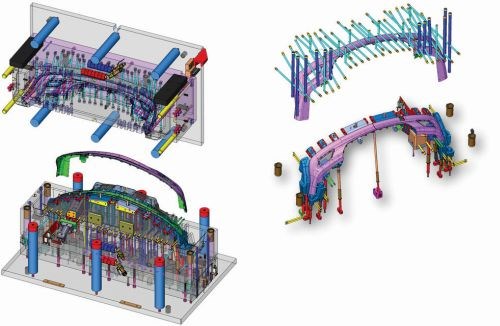

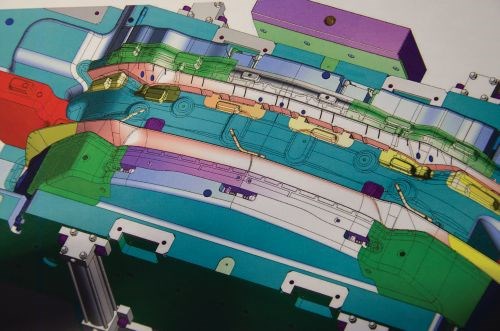

Yet, the capability with the most promise also seemed the most limited, at least for Unique’s purposes. Designed to alleviate the burden of repetitive tasks, the software’s component library stores CAD files for commonly used components, which can be called up as-needed according to job requirements. Street emphasizes that this feature provided a major step forward for Unique Tool & Gauge. At the same time, however, it whet the team’s appetite for what else might be possible. Rather than individual components, they asked themselves, why not store fully-assembled mold-base templates that correspond to every possible combination of customer requirements? Thus began a multi-year collaboration with Cimatron that culminated in the development of what Street calls “smart bases.”

Of course, the sheer number of possible combinations made creating the templates a time-consuming task. Every customer has its own “standards book,” typically massive tomes that, as Street puts it, “can require a law degree to read.” Moreover, standards vary not just by customer, but also by the type of mold and the intricacies of each individual injection press.

For instance, all mold bases from one particular customer might have V-shaped notches that interface with its injection machines. However, other requirements, such as whether to employ electrical plugs or a hot drop, differ from tool to tool. Adding to design complexity is the fact that few press manufacturers take the same approach to, say, knockout bar connectors or the locations of water fittings, and any given customer might have any number of different presses. Even press make and model don’t tell the whole story, because customers with identical machines might set them up differently. Nonetheless, the team recognized that storing this information in the system one time would be far preferable to the previous, painstaking practice of starting from scratch on every new job.

However, configuring the templates was only the first step. The company also had to deal with the fact that any given injection press can accommodate a wide range of tool sizes. Having templates for mold bases that meet customer expectations and account for individual press configurations is one thing, Street explains. Re-sizing a base template for every job, a task that would typically require manually adjusting the position of each and every component, is quite another. Plus, there’s always the potential of an engineering change altering the dimensions or configuration of the base assembly. “We didn’t want some of our top brains spending their time on such tedium,” he says. “We wanted them figuring out slides, ejectors and everything else that actually makes the tool work.”

With input from Sridharan, Unique’s design engineers set about developing mathematical formulas that enable the software to re-size bases with just a few keystrokes. At its essence, this task involved tying one feature to another—move this screw over so much, and an adjacent screw moves to match. “Essentially, everything is formulized, down to the stroke of the springs,” Street says.

Suffice to say the company’s effort paid off. For one, the “smart base” templates limit the risk of error. Moreover, designers can not only direct their attention to the most important aspects of a tool, but also take full advantage of the software’s other capabilities, such as simulating the operation of even the most complex molds. “The animation function is a tool that comes with Cimatron, but you have to know how and when to use it,” Street explains. “It’s not just a button click … you have to set up the parameters and constraints right.”

Supercomputing

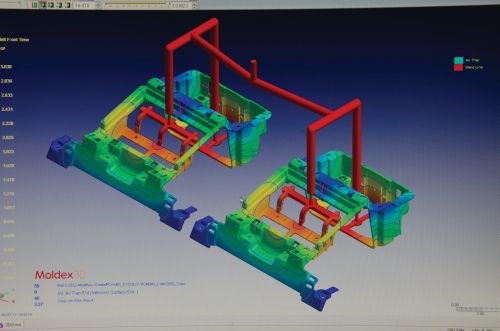

Despite the substantial time savings, automated programming did nothing to alleviate lengthy calculation times when opening large files, rendering solids and generating complex tool paths, Street says. This was also an issue with larger files in Moldex3D, EPS FloTek, the mold-flow simulation software Unique purchased as a package deal with Cimatron. Dealing with these issues required investing in 12 newer, faster computers, 11 for Cimatron and one for Moldex3D, as well as a Superbox, a Cimatron product.

Notably, the 12 new workstations weren’t just off-the-shelf purchases. Here again, the team proved willing to make the effort to push technology to the max. Again, they leveraged the input of Sridharan and, this time, Moldex3D representatives as well. The goal? Building customized computers designed specifically to take advantage of how the software interfaces with the hardware on which it runs.

Given two different programs, this required developing two different types of computers, but the time and effort paid off. “The recommended hardware configuration for Moldex3D isn’t even half as fast as the system we built,” says Simon Allcock, Unique’s R&D specialist, who spearheaded the effort to develop the custom workstations. “By performing multiple mold-flow simulations in the same time it would take others to do just one, we can make more modifications and arrive more quickly at better designs. This is more cost-effective for us, the hot runner supplier and the customer alike.”

As for Cimatron, near-instantaneous calculations ensure programmers can spend their time programming rather than waiting for their computers to crunch numbers. Allcock estimates that as recently as five years ago, this might have consumed as much as three hours of a programmer’s time on any given workday. He also points out that some of these gains are due not to the customized workstations, but to off-the-shelf technology: the Superbox, a plug-and-play product from Cimatron that’s designed just for this purpose. Able to calculate as many as five tool paths simultaneously, the device frees the programmer’s own computer to do other work in the meantime. “It’s calculation delegation,” Street says.

Never Satisfied

Unique Tool & Gauge continues to coax additional gain from its software and hardware resources. For instance, Allcock says he is busy developing a customized version of the Superbox to push the benefits of parallel processing even further. Mean-while, the team continues to consult regularly with Cimatron about how else the software might be adapted to suit the toolmaker’s unique needs. Examples include further enhancing automation in electrode manufacturing and eliminating bill of material (BOM) errors by improving synergy between design and purchasing.

The company continues to move forward with other new technology as well, and, as of late, new people, too. Just last fall, it announced a $3.5 million investment and new equipment and a push to hire 30 new employees. Yet, King says these investments might not have been as feasible without productivity gains derived from automating design and speeding calculation times. Doing so required not just new software, but a commitment to not shying away from pursuing needed standardization, even in the face of a diverse range of work. The specific route to get there may differ from company to company, but where there’s a will, the right technology supplier can help provide a way. “We’ve used the tools Cimatron has given us to apply the system for our specific needs,” King says.

3D Systems - Cimatron Software

Related Content

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreRead Next

Refusing to Settle

This toolmaker’s efforts with design software and aluminum production tooling reveals a drive to challenge conventional practices and push capabilities to the limit.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More