Next Chapter Manufacturing

3650 Broadmoor Ave. SE

Suite 102

Grand Rapids, MI 49512 US

616-383-9900

hello@nxcmfg.com

nxcmfg.com

IS THIS YOUR COMPANY?

As Seen On MoldMaking Technology

Next Chapter Manufacturing Supplies the Following Products

- Blow Molds

- Compression Molds

- Cooling Systems

- Core Pins

- Die Cast Dies

- Ejector Pins, or "Knock-out Pins"

- Extrusion Blow Molds

- Extrusion Molds

- Fixtures

- Foam Molds

- Injection Molds

- Liquid Injection Blow Molds

- Mold Design Services

- Part & Tooling Production Services—Additive Manufacturing

- Prototype Tooling Services

- Prototype/Short-run/Injection Molding Services

- Stretch Blow Molds

- Thermoform Molds

- Training and Consultancy Services—Additive Manufacturing

Trade Names Offered by Next Chapter Manufacturing

Editorial, News, and Products

-

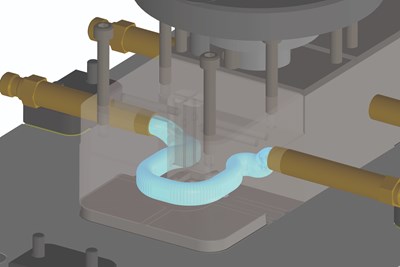

How to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

-

Do You Remember?...The Best of MMT September

Say, do you remember? These top-viewed MMT articles from September?

-

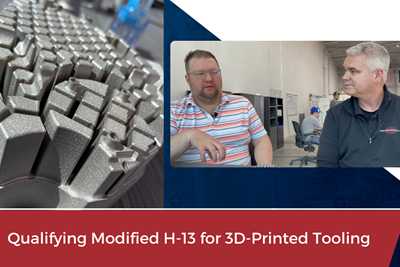

VIDEO: Qualifying Modified H-13 for 3D-Printed Tooling

Next Chapter Manufacturing and International Mold Steel discuss their partnership to qualify a modified H-13 for tooling applications.

-

Technology and Sourcing Guide 2023: Additive Manufacturing

3D printing, or additive manufacturing, simplifies the moldmaking process by making mold inserts, mold components, end-use parts and ancillary equipment. Access this exclusive, online-only content, including a suppliers list, AM products and more.

-

YCM Alliance Technical Center Grand Opening Highlights Customer-Centric Focus

The two-day event celebrated at the end of May brought in 300+ OEM and job shop customers, dealers and industry vendors for mold/die, general parts and high-speed machine demonstrations as well as industry expert presentations.

-

New Michigan Technical Center for YCM Alliance

YCM Alliance held a grand opening of its new Technical Center in Sterling Heights, Michigan, last week, which is the first in a series of centers designed to showcase and demo machining solutions for die and mold machining, ultra-high-speed machining and general parts machining.

-

A 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

-

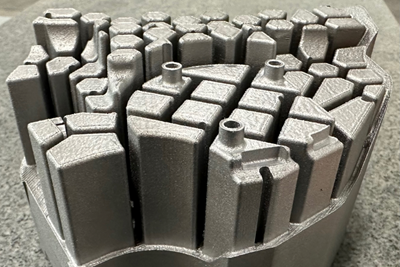

Qualified Tool Steel Enhances Thermal Transfer, Long Tool Life

Next Chapter Manufacturing has successfully qualified HTC-45 tool steel, an optimized version of H13, to support better thermal transfer and faster cycle times for molders and die-casters.

-

Next Chapter Manufacturing Expands Into Medical Industry, Initiates NXCMED

Additive surgical company will deliver surgical device solutions, such as implants and complex surgical devices, through disruptive design and 3D printing technologies.

-

PTXPO Preview 2023: 3D Printing, Machining and Cutting Tools Technology and Services

The Moldmaking Pavilion powered by Amerimold is one of seven pavilions returning to PTXPO. Take a moment to familiarize yourself with those exhibitors that can fulfill your 3D printing and machining needs.

-

MoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

-

Small, Agile Mold Builder Keeps Speed and Accuracy at the Forefront

Michigan-based Zero Tolerance tests the limits of moldmaking and molding with teamwork and technology that permits changes on the fly.

-

Two Reasons to Form Additive Tooling Partnerships

Partnering with experienced 3D printing resources is essential to remaining competitive in today’s ever-evolving moldmaking industry.

-

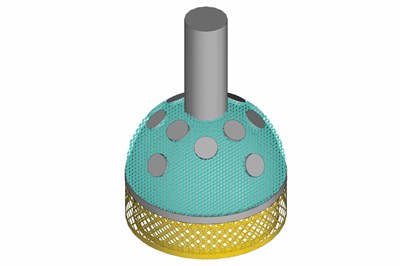

VIDEO: How can 3D Printed Tooling Improve Injection Mold Venting?

Proper venting is one of a mold builders toughest challenges as molders struggle to keep vents free flowing in production. Learn how to apply 3D printing to mold venting and the benefits of additive venting inserts.

-

Variable Density-Coated Tool Steel for High-Wear Molds

A mold builder can have an abundance of venting and fully dense solid areas in steel by using variable density sintering to eliminate gas trap defects in high-wear molds.

-

Mold in a Day Technology Slashes Tool Production, Eliminates Supply Chain Headache

Next Chapter Manufacturing says its Mold in a Day additive manufacturing technology slashes the production of tooling down to hours while maintaining the same quality and tolerance standards of conventional molds.

-

Wepco Plastics Inc. CFO Shares Three Favorite Articles: Social Stories, Bright Spots and Sticking to the Plan

MMT’s Editorial Advisory Board shares its top MoldMaking Technology articles of all time and how this content has been valuable to their businesses.

-

“Molds Make a Difference” at the Plastics Technology Expo

That was the sentiment of every person who came up to the MoldMaking Technology booth during last week’s Plastics Technology Expo to grab their giveaway “Molds Make” t-shirt after working the aisles seeking technology and process solutions and making new business connections.

-

Learn About Industry Topics and Emerging Technologies at PTXPO

Aside from being a great opportunity to network with other industry professionals, PTXPO will have numerous educational sessions about hot topics and emerging technologies.

-

Penn Erie Tooling Division General Manager Shares Three Favorite Articles: People, Pins and Passing It On

MMT’s Editorial Advisory Board shares its top MoldMaking Technology articles and how this content has been valuable to their businesses.

-

MoldMaking Technology's Top-Viewed Content 2021: Features

These popular articles from 2021 highlight a range of topics, from the 2021 Leadtime Leader, tips on supplying cooling to additive tooling and best practices to improve efficiency. Revisit some of your favorites, or take a look at what you’ve missed.

-

Here Are Your Top 10 Most-Read Features of 2021

A list of the most-viewed features in MoldMaking Technology from January to November 2021.

-

3D-Printed Stainless Steel Vent Pins Produce Defect-Free, Injection-Molded Parts

The Innovent Pin from Next Chapter Manufacturing is said to offer 10-15 times the volume of venting over traditional venting methods with suitability for filled and unfilled plastic resin grades.

-

Advancing the Mold with Amerimold 2021 Education Sessions

With an expanded three day schedule, more free educational sessions are being offered than ever before, including a range of sessions from Amerimold exhibitors.

-

Vented Ejector Pins Targets More Efficient Gas Removal for Molds

Next Chapter Manufacturing presents its 3D-printed NXC vented ejector pins which offers an integrated porous core to enable gas to pass through the face of the pin and vent out the side, avoiding gas traps.

-

How to Design a Mold with Additive Tooling

Designing molds with additive tooling implementation in mind requires blending traditional mold standards with innovative new ideas of what is possible to push the limits of mold performance.

-

How to Use Additive Tooling in Difficult-to-Cool Areas of a Mold

Difficult-to-cool areas of a mold cost cycle time, making the perfect application for additive tooling, including retrofitting an existing tool with lifters, slides and high wear areas.

-

MMT Chats: Fighting COVID-19 with Collaboration

Next Chapter Manufacturing, Muskegon Community College, PCS Company and Concept Molds chat about a coalition they formed to produce face shields to help fight COVID-19.

-

How to Maintain Additive Tooling

Implementing additive tooling into a mold can be a daunting task, but maintaining it over the life of the tool can be straight-up scary. Here are three steps to include in your maintenance plan.

-

How to Use a Conformally Cooled Sprue Bushing to Reduce Cycle Time and Ease Cost Pressures

Use of a new conformally cooled sprue bushing helped solve Midwest Mold Services’ problem with a big sprue that was hard to cool and preventing faster ejection times.

-

Additive Tooling Goes Beyond Conformally Cooled Inserts to Simplify the Mold Build Process

Three ways that additive tooling is moving past conformal cooling to bring speed and efficiency to the overall tooling process.

-

H13 Laser Sintering Process for Robust Tooling

Partnership is the key to developing advanced process parameters for producing robust H13 tooling using laser sintering process.

-

Selling the Value of Additive Tooling in a Mold

Gaining molder buy-in for a conformal-cooled mold insert requires communicating the mold’s total cost of ownership over the life of the project.

-

Capability to 3D Print H13 Delivers Robust Tooling

Direct metal laser sintering H13 material plays a big role in how this company has differentiated itself from the competition.