Selling the Value of Additive Tooling in a Mold

Gaining molder buy-in for a conformal-cooled mold insert requires communicating the mold’s total cost of ownership over the life of the project.

Customers predominantly evaluate mold builders by the price of the mold, and they often do not consider the value that mold provides to the molder. This remains one of the biggest challenges in mold manufacturing today, and additive tooling with conformal cooling adds to this challenge. The key is the mold builder communicating the overall value the mold brings to the molder, so he or she can accurately evaluate that mold’s total cost of ownership over the life of the project.

One common question is “What exactly is additive tooling?” For moldmakers, additive tooling means using 3D printing to produce tooling out of metal, specifically tool steels, that will be used to produce high-volume class 101 molds. This also means sub-inserts that will go into larger molds or mold bases to make this technology economical for implementation. In the near future, this is expected to expand, enabling the production of complete mold plate cavities that form the plastic.

Conventional moldmaking starts with a block of steel that moves through various machining operations (milling, drilling, EDM, turning, grinding) that subtract material to achieve the final shape. 3D mold insert printing starts with a large volume of fine metal powder (particle size 15-45 microns) or wire that is added layer by layer to complete the net shape within 95% of the finished shape. Another option is a hybrid machine tool that combines the additive process of building the insert layer by layer with finish machining that yields an insert ready for fitting directly into the mold.

Adding It Up for the Mold Builder

When implementing additive tooling into the moldmaking workflow, a mold builder should consider the value of improving mold manufacturing efficiency and not only consider the incremental cost of the purchased insert.

For example, if a mold builder outsources the additive insert work, a mold builder receives the insert near net shape with 0.015-0.040-inch machining stock, which requires minimal machining. This outcome translates up to a 50% reduction in carbon costs, as the mold builder only needs to finish EDM to achieve fine detail or tolerance. Additive tooling also reduces other consumables, such as expensive cutters that are not necessary for roughing and semi-finishing. A mold builder can jump directly to finish machining using an additive insert, which reduces cutting hours.

Other benefits include quick and efficient setups with additively manufactured inserts designed and built to accommodate pallet and fixturing systems. Additive tooling inserts are made to near net shape, making the organic shapes difficult to hold for finish machining. By integrating pallet and fixture mounting features into the insert build, the transition from the finished additive part to accurately locating the part on a pallet is simplified. Also, additive tooling eliminates the need for hole popping because hole feature sizes are 0.011-inch, which allows built-in wire EDM start holes. All of this means the number of steps from start to finish is fewer, reducing finish machining costs and lead times.

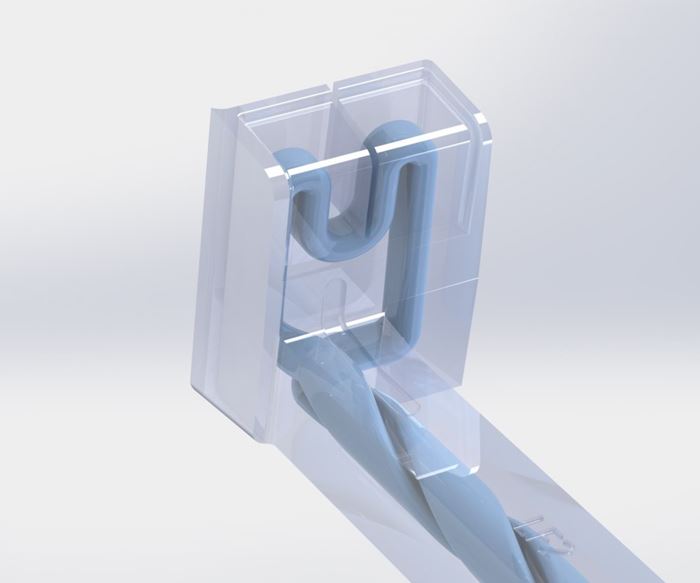

Another benefit of 3D printing is conformally cooled mold inserts. Conformal cooling is ideal for complex contours where drilled waterlines, baffles and bubblers cannot provide a consistent temperature profile across the contour of the tool. Conformal cooling is more effective for providing a consistent mold temperature profile across the molding surface. Other areas to consider are proper cooling at the gate or a hot runner drop to maintain proper control and thermal consistency.

When implementing additive tooling into the moldmaking workflow, a mold builder should consider the value of improving mold manufacturing efficiency and not only consider the incremental cost of the purchased insert.

Adding It Up for the Molder

While the perceived costs of implementing additive tooling into molds is a deterrent to many mold builders, the true value is most beneficial for injection molders who experience better cycle times, elimination of molding defects and improved on-time customer delivery.

A mold builder must work with each customer to calculate the true cost of additive tooling, driving the value upfront and providing cost savings throughout the life of the mold. A mold builder can drive value upfront by asking the molder to identify any challenges they expect to see in production for which the mold builder provides a solution that will prevent those problems over the life of the tool.

For example, the mold builder uses a moldflow analysis to identify a hot spot in the mold that would result in warp and provides a unique way of cooling that area, such as conformal cooling. This solution will help the molder see that the defect will not occur during production. Now the molder will understand the impact and value of investing in conformal cooling versus dealing with the prior high scrap rates and customer complaints. This upfront strategy will also set a mold builder’s tooling apart from the competition, especially when it comes to low-cost country sourced tooling.

Many mold builders do not concern themselves with process and cycle times, but these two factors are just as important as a mold’s lead time, price and quality. One way to communicate these times to your customers is data that shows the expected result. Using reliable tools like mold flow simulation will visualize the process and prove out the savings before making critical mold design decisions that will affect the mold build and its performance.

Although mold builders use simulation to determine gate and vent locations, they are not using the software to analyze cooling optimization options fully. When a mold builder does not take the extra step to find the most optimal cooling configuration, he or she is missing a big opportunity to demonstrate the potential production savings to the molder. If a mold builder models both conventional waterlines and conformal waterlines, and runs the simulations side-by-side, they can clearly show the difference in cooling time between the two options. The simulation also shows possible part quality enhancements to better calculate any expected savings with processing time and scrap.

Many mold builders do not concern themselves with process and cycle times, but these two factors are just as important as a mold’s lead time, price and quality.

Simulation may seem like a bit of extra work compared to just offering a tool quote, but taking that extra step will provide the total value of both the mold and molding process, which results in the most cost-effective solution for your customer. For example, if your $250,000 mold reduces cycle time and scrap, resulting in $100,000 in savings a year, this will quickly pay back the initial investment of additive tooling and provide $500,000 savings to the customer over the first five years of mold production. This conversation with a customer will not only emphasize additive tooling’s true value but also shows the customer that you are considering their best interests and looking beyond the mold. Focusing on these aspects also changes the conversation from only price and lead time to the total cost of tooling’s impact on the entire program.

When discussing additive tooling with a customer, remember that they need a complete molding solution, not just a mold. Maintain your focus on the value you can bring by doing what you do well. Then partner with a reputable company for conformal-cooled inserts that knows injection molding and molds to support your operation from design through delivery, even in the startup and process development of the mold.

About the Author

Jason Murphy

Jason Murphy is president and CEO of Next Chapter Manufacturing.

For More Information

Related Content

The Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D-printed parts.

Read MoreHow Hybrid Tooling Accelerates Product Development, Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

Read More3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreRead Next

How to Calculate the Full Cost of Additive Manufacturing

A true evaluation of additive includes a look at materials, speed, quality, scalability, and cost.

Read More3 Ways a Small Mold Builder Uses 3D Printing

How mold builder Byrne Tool + Design uses 3D printing for simultaneous mold manufacturing, conformal cooling and hybrid designs.

Read More3D Printing is Solidly in Moldmaking’s Future

Francine Petrucci, president of B A Die Mold Inc., calls 3D printing the elephant in the shop because its time is imminent and young people know it.

Read More

.jpg;maxWidth=300;quality=90)