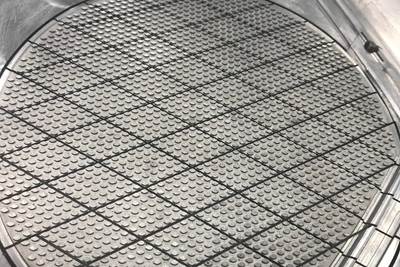

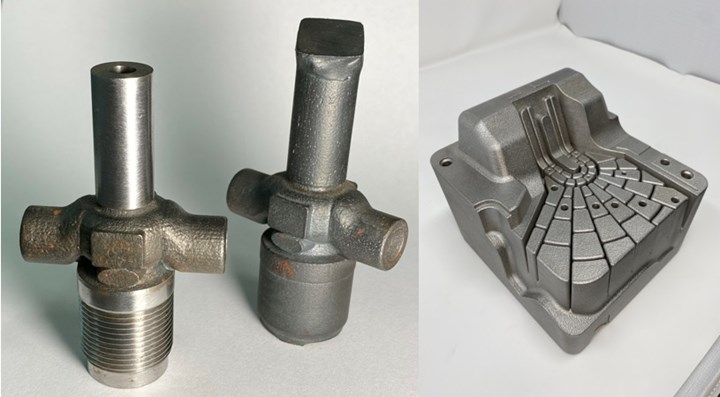

3D printing advancements and applications have gone from conformally cooled hot runner nozzles using a 3D-printed pattern to cast the part with integrated cooling circuits (left) to large DMLS 3D-printed parts in 420 stainless steel with integrated conformal cooling and InnoVent Technology for venting (right). Photo Credit: Next Chapter Manufacturing

Looking over the vast landscape of additive manufacturing (AM) technologies, the various material options and the number of experts in the market can leave you more confused than ever. However, 25 years ago, it was a vastly different landscape. So, here is a quick look at how technology has evolved from the mid-90s to 2023.

It All Started With a Problem

My journey into additive tooling began as a moldmaker with a problem to solve. In 1996, I worked with a hot runner company with technology built like a Swiss watch whose intricacies would often fail during the injection molding process. These systems were used to make automotive interiors and exteriors, which demand the parts to be flawless for painting or final finish. This required us to use cooling jackets to provide good cooling in the gate area and avoid gate blush and other cosmetic defects. These two-piece units were a work of machining art carved out of billets with thin walls and intricate cooling channels that were vacuum-brazed together to provide a complete cooling circuit in the hardest-to-cool areas of the mold. However, these units would frequently fail and the mold would be down, waiting on replacements.

Hence, the problem I needed to solve. I needed to keep the tip hot enough to flow plastic shot after shot, yet cool enough not to allow heat to dissipate into the mold steel, which would cause a visual defect. My solution was a nozzle tip with integrated cooling in a one-piece design. It sounds simple, but it proved to be a nearly impossible task.

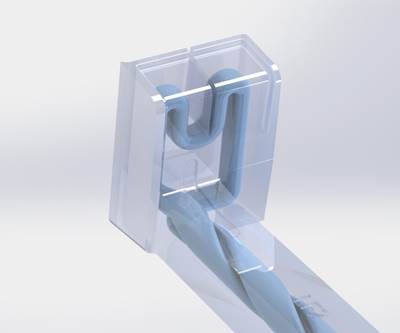

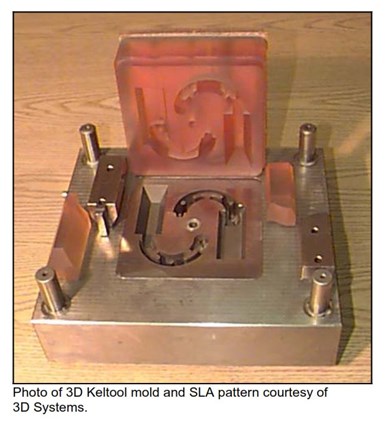

3D Keltool mold and SLA pattern. Photo Credit: Wohlers and Associates and 3D Systems

I was familiar with selective laser sintering (SLS) technology for plastics, but I needed a metal solution. So I turned to my investment casting experience. I thought I could make a pattern and then investment cast it, but the SLS resin was not a good candidate for use as a wax pattern. Then I came across a 3D printer designed for the jewelry industry and 3D printed wax, shaved the layer down using a milling head for a finer resolution, printed wax patterns and investment cast tool steel and then dissolved the shell material, which resulted in a very accurate investment cast of a hot runner nozzle with integrated cooling circuits.

Then I machined the threads and tight-tolerance surfaces. The results were terrific. I could run the mold with reasonable control at the hot runner tips and achieve good gate freeze-off without any issues with gate blush. Those nozzles ran for a long time without fatigue or cracking. I was hooked. I could now see that 3D printing for moldmaking was the solution to solve some of the most challenging problems the industry faced.

The 3D Printing Journey for Tooling

From that day on, new technologies were regularly introduced that could disrupt moldmaking. Here’s a look back at some AM technologies that used raw materials to build a plastic-forming core or cavity insert in a mold.

Plastics, SLS

In 2000, the terms RapidSteel and RapidTool were used interchangeably, but the former referred to the material and latter referred to the process for producing mold inserts and parts fast. Photo Credit: Wohlers and Associates, 3D Systems and Bastech.

3M Corp. developed the Keltool process in 1998, producing sintered metal cores and cavities from a master 3D-printed part made through stereolithography. The inserts are installed in a mold base to run up to a million injection cycles. 3D Systems purchased this technology as it was complementary to its own machine’s stereolithography process. This technology quickly became known as rapid tooling because what would typically take 12-18 weeks to produce could be done in half the time. At the same time, DTM launched its RapidSteel material, a steel and copper matrix sintered to form a complete insert. These were both cutting-edge technologies for reducing lead times, but many hurdles still existed.

Speed was the focus of this technology for those willing to pay a premium. In the early 2000s, there was almost a frenzy about the dramatic lead time reductions, and customers were willing to pay for this speed versus going offshore for low-cost tooling with long lead times. Then as speed increased, so did the need for improved part quality.

As industry designed and built thinner and thinner walled components, the focus turned to controlling the cooling rate and eliminating warp. For the part where conventional cooling was not possible, now conformal cooling came into play. I recall several projects with so many actions that there was no way to cool the part, which would then cause warpage. So, I calculated that printing the inserts was the most cost-effective approach.

Metal, DMLS

During this time, companies were starting to think more holistically about their budgets, like investing in good tooling now and enjoying a higher margin on the piece price later. Copper beryllium was also gaining popularity around this time; however, the high thermal conductive metals would not withstand the wear, so conformal cooling in tool steel with proper hardness was starting to take hold.

Now, companies like EOS, 3D Systems and Concept Laser started introducing direct metal laser sintering (DMLS) processes. However, the materials were limited to a handful of printable powders from feedstocks of the metal injection molding (MIM) industry. The most popular was maraging steel, as it offered the most promise for tooling compared to lesser steel, titanium or aluminum. However, moldmakers were uncomfortable with this material, so they often opted for the traditional route.

This technology made more sense than previous ones that used a binder you had to bake out and then sinter, leaving too much variation from the CAD solid model to the finished product. In addition, if something went wrong, you’d have to start over again, losing the advantage of speed.

Speed was the focus of this technology for those willing to pay a premium. Then as speed increased, so did the need for improved part quality.

When I started to use this process, the results were good, but they still had a few limitations:

- Waterlines could not be round as that would require support structures inside, obstructing the flow of the cooling circuit.

- Cooling channels had to be self-supporting, which meant they had to be teardrop-shaped, creating a stress point at a sharp corner prone to cracking. It also made the cooling circuit difficult to fit into a contour of a part between all the pins and other thin steel conditions.

- Density was between 85% and 89%, causing the micropores to leak and water to seep out.

- Plating waterlines was difficult.

- The surface finishes of the 3D-printed mold inserts were coarse.

- The high corrosion propensity of maraging steel could commonly corrode and plug the waterlines.

A grille mold with integrated InnoVent vents at every intersection for a total of 480 vents in the insert. Conformal cooling is also integrated into the mold for consistent cooling and faster cycle time. The insert is built on a larger billet to make the most cost-effective use of additive manufacturing (AM) coupled with subtractive machining. All of this is possible only through AM. Photo Credit: Next Chapter Manufacturing

Conformal Cooling

During this time, academic research was conducted on additively manufactured tooling and conformal cooling. Published papers revealed research in AM for industrial applications, but those in the trenches often ignored these. Some of the research was adopted by AM equipment manufacturers, but there was still a significant divide. Another disappointing trend was the rise of competition from Asian tooling suppliers. Most mold builders were just trying to pay the bills and compete against Asia instead of trying something new, like printing more efficient tooling.

While a handful of pioneers pushed for additive tooling by 2010, the general industry was quite resistant. By 2015, DMLS improved to a point where the density range was 95-99%, which was a stark improvement over the prior decade, giving mold builders the confidence to create water-tight cooling circuits and increase the wear of inserts. Some regularly got over one million cycles from commodity resins and 500,000 cycles from engineered resins.

Some machine builders took it a step further and developed hybrid machines that would additively build the inserts while subtractively machining them in the same machine. This approach showed promise for the future of integrating AM for moldmaking.

Tool Steels

Now moldmakers needed true tool steels and a guarantee that this was on par with billet tooling. By 2015, there was little development toward true tools steels. Most machine manufacturers were not open-platform, so they could not develop new material parameters. And material manufacturers could not print the desired tool steels, so they would make modifications and label the material as a “like” product, creating confusion among moldmakers and preventing wide adoption.

Around 2019, there was an explosion in AM technology specific to moldmaking and solving molders’ most challenging problems.

The material limitations also made it difficult to know how to perform secondary finish or repair work. These materials did not have the same properties for welding, texturing, nitriding, polishing and coatings. It was time to educate the plastics processors on maintaining 3D-printed tooling.

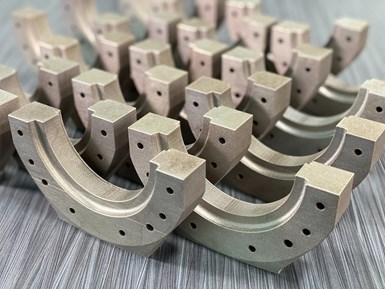

3D-printed curved slide inserts for forming threaded portions of a packaging mold, which enables more consistent cooling of the threads, reducing cycle time. Photo Credit: Next Chapter Manufacturing

Around 2019, there was an explosion in AM technology specific to moldmaking and solving molders’ most challenging problems. For example, variable density steel provides fully dense steel for shut-off and cosmetic areas, porous steel in precise locations to place venting exactly where required and off-the-shelf additively manufactured standard mold components like conformal-cooled sprue bushings and vented ejector pins.

Now in the 2020s, I believe we will see mold builders integrating AM on the moldmaking shop floor. This begs the question: Is additive right for me and my moldmaking operation? The answer is yes!

Related Content

3D Printing Innovates Hot Runner Manifold Design

Metal 3D printing combined with a conventionally machined manifold block overcomes flow shadows on valve gates and offers faster color changes while providing closer system pitch centerlines between cavities.

Read MoreMMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreLarge Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read MoreRead Next

Two Reasons to Form Additive Tooling Partnerships

Partnering with experienced 3D printing resources is essential to remaining competitive in today’s ever-evolving moldmaking industry.

Read MoreHow to Improve Mold Venting with Metal Additive Manufacturing

Patented 3D-printed mold insert design rapidly evacuates gases while preventing plastic flash-through, eliminates costly maintenance and need for press-side temperature-control units.

Read MoreSelling the Value of Additive Tooling in a Mold

Gaining molder buy-in for a conformal-cooled mold insert requires communicating the mold’s total cost of ownership over the life of the project.

Read More