Qualified Tool Steel Enhances Thermal Transfer, Long Tool Life

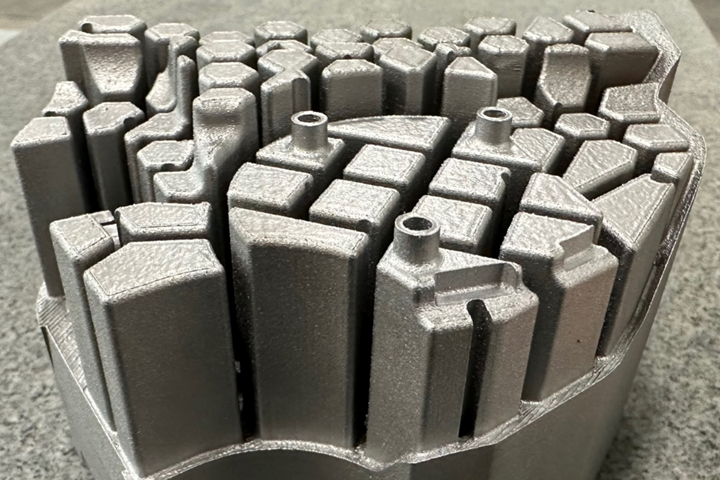

Next Chapter Manufacturing has successfully qualified HTC-45 tool steel, an optimized version of H13, to support better thermal transfer and faster cycle times for molders and die-casters.

Next Chapter Manufacturing, known for its ability to print true tool steels, expands its qualified materials to include HTC-45 which is an optimized H13 that eliminates common cracking and has increased thermal conductivity that is reported to be twice that of maraging steel.

“The HTC-45 enables us to push the limits of additive manufactured molds and dies by providing longer wear tool life through better thermal transfer and faster cycle times for molders and die-casters alike,” Jason Murphy, owner and CEO, Next Chapter Manufacturing, says.

Additively manufactured molds with conformal cooling channels have been used to enhance the cooling efficiency of plastic and die-casting molds. H13 and maraging steel powders are commonly used in 3D printing, but each has its own challenges.

H13 powder, for instance, is difficult to build without cracking while the low thermal conductivity of maraging powder leads to higher thermal stress which promotes cracking from water cooling channels and heat checking on the design surface.

Tackling these problems, Daido Steel developed DAP-AM HTC 40 and DAP-AM HTC 45 by optimizing the chemical composition of H13. According to Paul Britton of International Mold Steel (IMS), the distributor of DAP-AM HTC powders, “we are excited that Next Chapter Manufacturing has validated DAP-AM HTC powders in their facility. Their expertise in AM printing combined with the unique characteristics of DAP-AM HTC powders is a game changer for the moldmaking community.”

International Mold Steel is a Daido Steel partner company that consults with Fortune 500 companies to deliver cutting-edge solutions in engineered tool and alloy steel in North America.

Related Content

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

-

Mold Materials, 3D Printing Technologies for Next-Gen Moldmaking

As moldmaking advances, so too do the materials and processes involved in their efficient production, including these latest mold materials and 3D printing technologies.

-

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.