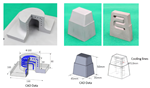

Jason Murphy of Next Chapter Manufacturing has been contributing content to MoldMaking Technology for the past few years solely to educate this niche on the advancements and benefits of 3D-printed tooling. However, today he sits down with Doug Mitchell with International Mold Steel to discuss how they have worked together to successfully qualify HTC-45 tool steel for the plastics and die casting market, which offers twice the thermal conductivity of maraging steel.

They also discuss conformal cooling, higher thermal conductivity applications in true tool steels that provide improved wear, longevity, cycle time and cooling as well as common barriers to metal AM adoption in the tooling sectors and the importance of working with suppliers to get into trials to better understand the technology.

Watch the video interview above.

For more video content from MMT, visit our Videos page

Related Content

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.