MMT Blog

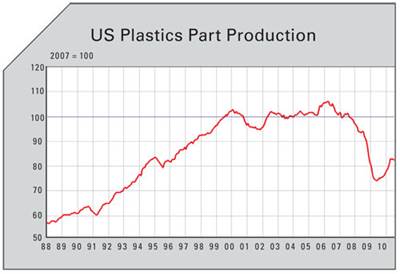

The Plastics Industry’s Lost Decade

Every month, the Federal Reserve Board compiles and reports production data for the major manufacturing segments in the U.S. industrial sector.

Read MoreHow to Maximize Your Marketing Budget

What do you do for your customers that keeps them coming back?

Read MoreCreating a Competitive Cost Model in the U.S.

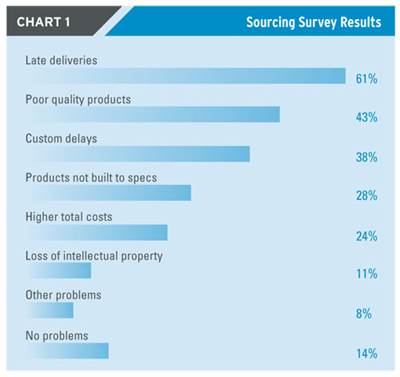

Recent China trends present opportunities for U.S. manufacturers and supply chains.

Read MorePredictive Maintenance: How to Keep Machinery Running

The moldmaking industry can experience cost-saving benefits and crisis aversion with the right predictive maintenance program.

Read MoreMeasuring Massive Molds

When working with massive molds, the penalties of rework are greater than those of smaller sized molds.

Read MoreJustifying a Mold Rebuild Using Collapsible Core Technology

Technical advantages prove there is ample reason to explore rebuilding—or retrofitting—traditional unscrewing tools.

Read MoreIs It Time for Some Preventive Mold and Hot Runner Maintenance?

Points to consider when planning preventive maintenance on a tool.

Read MoreLe Bac Plastic Mold: Old-World Craftsmanship and Modern Technology

Le Bac’s culture is one of creativity and teamwork that blends modern technology and Old World craftsmanship.

Read MoreCreating Constructive Change: Training

Training is the most discussed area in a shop with the least amount of action.

Read MoreAutomation Division Paves Way to New Customers

Ohio-based FPM Tooling and Automation found new unconventional markets when it launched a division focused on automotive.

Read MoreSome Non-Partisan, Yet Totally American Advice For the New Congress

Bill Wood looks to the future, and what may be in store for mold makers over the next 12 months.

Read MoreMold Business Index: Underlying Data Show Strong Index Components

The total Mold Business Index is a weighted average of the Sub-Indices for new orders, production, employees, backlog, exports, and supplier deliveries. The Mold Business Index (MBI) for October 2010 is 51.3.

Read More