MMT Blog

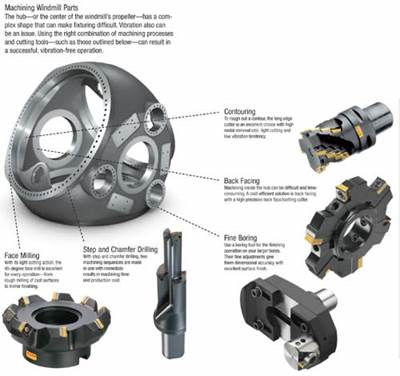

Wind Power Industry Opportunities Blowing Our Way

Moldmakers wishing to tap into this growing market should do their research and reach out to both wind power industry experts to learn about windmills and cutting tool suppliers to learn what it takes to enter this field.

Read MoreThe Digital Office: Improving Efficiency and Productivity in Your Back Office

Simple and affordable document management solutions that can have a powerful impact on your shop’s bottom line.

Read MoreAmateurs Talk Tactics, Professionals Talk Logistics

A friend of mine likes to use this phrase from the military to guide and assess business strategies. I think it applies to the U.S. as a guide to regain and grow a strong manufacturing base. “We need a clearly enunciated, lucid, pragmatic national manufacturing policy in the U.S. And we need it now.” You may read that and think it’s an obvious thing to say. But if it is, why don’t we have one?

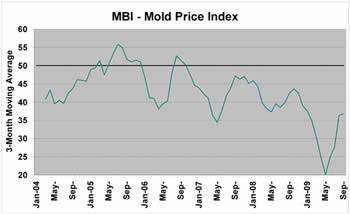

Read MoreActivity Levels Indicate Uptrend Starting

55.2 Total Mold Business Index for September 2009 The total Mold Business Index is a weighted average of the sub-indices for new orders, production, employees, backlog, exports and supplier deliveries

Read MoreAdvanced Toolpaths Improve Cutter Performance in Difficult Materials

Trochoidal toolpaths are available on most CAD/CAM systems, yet are rarely used or even known. By using trochoidal toolpaths and hybrid trochoidal toolpaths you can successfully machine exotic materials.

Read MoreAnalysis of the Additive Manufacturing (AM) Industry Worldwide, Part I

After more than two decades of research, development and use, the additive manufacturing industry continues to expand with the introduction of new technologies, methods and applications. Additive processes have had a tremendous impact on design and manufacturing, and this impact will continue to grow in the coming years.

Read MoreTooling Transfer: Sampling Success

Fifteen steps to facilitate a smooth tool transfer between the OEM, new molder and your shop.

Read More3-D Laser Scanning Opens the Door to Inspection And Reverse Engineering for Moldmakers

Next-generation scanning technology precisely captures large and small molds.

Read MoreIt’s a Small World in the Electronics Market

As electronics devices continue to shrink in size, an opportunity arises to enter the world of micro moldmaking to expand your business

Read MoreTo Rail or Not to Rail

One of the most interesting parts of performing a maintenance capability assessment (MCA) in mold plants around the globe is observing the different styles practiced when repair technicians work on molds. When talking to repair techs about why they like a particular method or tool it is easy to see why they would think there is only one way to do things. It’s simply how they were taught by the older, tenured repair technicians.

Read MoreSupply Chain Risk, Volatility Offer Opportunity

As I write this, reports are circulating about the U.S. economy showing signs of rebounding. But until unemployment begins to rise with any significance and housing foreclosures slow down, I’m skeptical. Without demand, there’s no supply. But as precarious as things are—and as far as U.S. manufacturing has suffered during and before this Great Recession—opportunities do still exist for machining businesses in the U.S.

Read More