MMT Blog

Invent a Product—Not Just Its Mold

When Wayne Sikorcin, owner of Craftsman Tool & Mold Co. (Aurora, IL)—a moldmaker turned mold base builder—got frustrated tying water balloons at a family picnic several years ago, he decided to turn that frustration into innovation by using his moldmaking background, experience and connections to develop, design, prototype and mold a device that would tie a knot on a water balloon.

Read MoreMichigan Tooling Group: A Total Solutions Provider

Established in 2005, the Michigan Tooling Group (MTG) was formed to be a Best in Class, total solutions provider for tooling and related services.

Read MoreStreet Cred: Capitalizing On Current Conditions And Best Practices

There are areas of opportunity for your business, but all may require changing or adapting to capitalize. Change is the single most difficult characteristic to successfully manage for any business at any stage, let alone in times like these when change is so prevalent and harsh.

Read MoreDoing the Math on Your Moldmaker's Value

About this series: For those charged with raising the sales of a mold building company, differentiating one’s company from the competition is fundamental. This quarterly series features actual examples of the front-line representative of a mold building company presenting new approaches to improve the customer’s profitability.

Read MorePolishing: Trends and Opportunities

Polishing industry trends “mirror” those in the moldmaking industry: shorter leadtimes, new growth opportunities/diversification and process improvement via technology advances.

Read MoreLaser Sintering And Conformal Cooling Channels

Moldmakers who are interested in exploring conformal cooling, but are concerned about its complexity and expense need to understand two things: it is neither complex nor expensive.

Read MorePrepare for a New Economy with Three Critical Investments

It’s time for mold manufacturers to use the experience they’ve gained as craftsmen to develop new opportunities for their businesses.

Read MoreCAD/CAM/CAE Integration Eases Flow Simulation

Moldmakers benefit from having flow simulation as part of the CAD/CAM environment—reducing the time and effort involved in running a flow analysis study and getting the product to market.

Read MoreHow to Get the Most Out of Your Control

If the spindle is the heart of the machining center, the control is the brain. This article will help you explore whether it’s time to expand your brain and find new efficiencies to increase profitability.

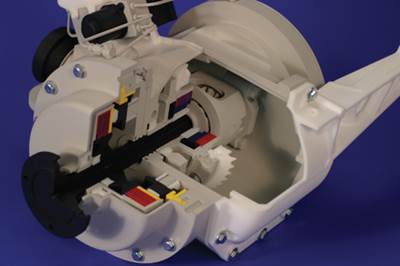

Read MoreTriangle Tool: Product-to-Tool Service

This Large Shop Leadtime Leader Winner penetrates new markets with complete product-to-tool service while investing in technology.

Read MorePrototyping Checklist: How to Choose

Today there are many prototyping technologies to support the full development cycle of a product from initial idea to manufacturing full-scale parts to low-volume production.

Read More