MMT Blog

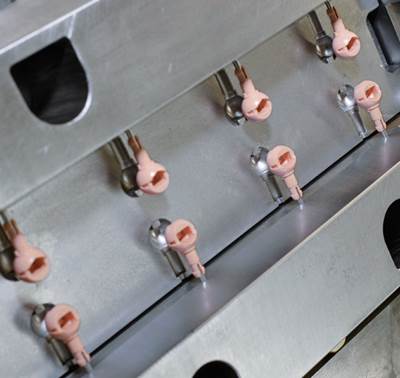

From the Field: Programming Software for Producing Playmobile Toy Molds

If it is still the norm in many tool- and moldmaking businesses to carry out programming either offline or directly on the machine, then the Playmobil example shows that a combination of both provides a lot of scope for creating and implementing new ideas.

Read MoreIt Is Time to Think About Business Continuity Planning

As the end of 2010 approaches, many businesses are taking some time to reflect on the past year and look ahead to 2011.

Read MoreSavings from the Front Lines: Rebuilding Saves Molders Money

This quarterly series features actual examples of a front-line mold building company presenting new approaches to improve the customer's profitability.

Read MoreBerrien Tool Coalition: A Marketing Edge

This group of companies delivers a full-systems approach to manufacturing—art to part and every-thing in between.

Read MoreMachine Tool Expandability Through Efficient Retrofitting

Considerations for determining if retrofitting is the appropriate and economical solution for your shop.

Read MoreEarly Collaboration, Part Design Involvement Key to Global Growth in Packaging

This mold manufacturer has achieved success by partnering with manufacturers in the packaging and closure markets on innovative plastic part designs—not simply providing a mold quote.

Read MoreSilicones Enhance Mold Design, Improve Performance

Silicones have been developed that provide primer-less adhesion to a variety of thermoplastic resins and are optimal for multi-component silicone-to-plastic molding.

Read MoreEvaluating Mold Quality

Quality is the name of the game in manufacturing. It’s not just about quality products, it’s about quality processes—from receiving to shipping, TQM, QA, quality service and delivery. Every facet of the manufacturing process has been assigned standards and how well those standards are met is an indication of the quality of that particular product, process or service. Quality products require quality materials, processes, equipment and tooling—specifically in the case of injection molded parts, quality molds.

Read MoreA Refurbishing To-Do List

The following steps represent a major refurbishment that will increase tooling life and reduce the cost of manufacturing and secondary operations in molding facilities.

Read MoreConfigured Components Help Save Time And Costs, and Maximize Efficiency

How to achieve big cost and time savings in your mold work by streamlining the mold design and ordering process. How using standard mold components can enable you to spend more time designing and building molds instead of all the components that go into them.

Read MoreFinding Your Voice

We bounced the idea around for weeks and finally on the morning of this September 11th, my husband and I looked at each other and said, “It’s time.

Read MoreHow to Boost Lean Manufacturing with Ultrasonic Mold Cleaning

With its considerable cost savings and reduction in personnel and time, ultrasonic cleaning is a natural corollary to lean manufacturing for the moldmaking industry.

Read More