Le Bac Plastic Mold: Old-World Craftsmanship and Modern Technology

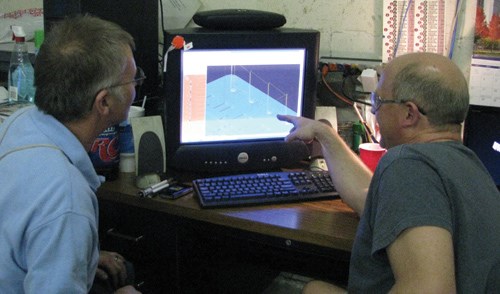

Le Bac’s culture is one of creativity and teamwork that blends modern technology and Old World craftsmanship.

It only took money from their savings account to purchase a manual milling machine and a sublet factory unit for Ron and Audrey Backman to start Le Bac Plastic Mold (Addison, IL) back in 1978. Since its inception, the company has doubled in physical size and employs six people to manufacture molds in the appliance, construction, sporting goods, hand-held tools and garden tools, and medical products industries.

According to Audrey, as the industry has evolved over the years from an individual craftsman approach to a more industrialized trade, Le Bac has consistently provided quality tooling, molds, prototyping and related manufacturing services to the plastics industry—including the ability to design, manufacture, revise, repair, restore and creatively engineer any mold. “The company culture of our close-knit team is one of creative and cooperative teamwork blending modern technology with Old World craftsmanship,” she comments. “This allows us to adapt to the rising needs and expectations of our customers.”

Customer Relations

Fortunately Ron and Audrey share the same philosophy when it comes to running their shop. “While embracing moldmaking as an industrialized manufacturing process, we still operate half the time as a traditional moldmaking company,” Ron elaborates. “Our CNC operators and engineers were all trained as classical moldmakers, and have come to the ‘computer age’ more slowly; but their deeper knowledge base helps them uncover problems as they develop, and before serious issues arise. This makes us more flexible and better able to meet our organizational goal of being team problem solvers.

“I think customers pick us because we usually produce a mold that is moderately priced with a quality level that is higher than the price would indicate,” Ron continues. “They pick Le Bac because if there are problems with the mold, we do house calls and an experienced employee—or the owner—works on-site to fix the glitch.”

Audrey agrees. “We have close partnerships with each of our customers,” she states. “Our specialty is in working with them as if we were their in-house mold builders. Because of our mixture of traditional and new technologies and our highly trained team, we are able to price competitively, deliver on time, and meet today’s tight production schedules. Our goal is to build a mold that produces good parts ‘right out of the box’. However, we also are able to offer what we call ‘creeping featurism’, or the ability to change on the fly. If a customer suddenly discovers that a dimension needs to be different, we can adapt to that change without sacrificing quality or delivery.”

Rising to Challenges

Finding new talent—a challenge universal to the industry—also affects Le Bac, although Audrey points out that potential employees are approaching them. “We continue to look for highly trained moldmakers who can work as a team,” Audrey says. “Back in the old days of craftsmanship tool building, one man would build a mold from start to finish, with assistance from apprentices. The fine engineering minds of moldmakers are built to communicate well with metal, not necessarily with others. So we look for tool builders with strong moldmaking experience who can communicate with team members and customers.”

Ron believes that the full-service mold shop is slowly becoming a thing of the past. “I don’t see any ‘30-somethings’ starting their own businesses, biting at my heels and hungry for this kind of innovation and success. There may be some younger toolmakers doing small sections of machining, or niche moldmaking, but I don’t know of anyone taking the full responsibility for every component: quality, delivery dates, outside services, etc. that today’s moldmaker must take on.

“It dismays me to see what I call micro-thinking when I believe we need to be looking larger and engaging in macro-thinking,” Ron continues. “For example, when I read about other shops debating whether the digital representations of their mold designs belong to them or the customer, I have a different perspective. I think, ‘I’m happy for you to have the digital design today. In a very short time, I will have innovated more than what is being done today—using new materials, programs and approaches.”

A Job Well Done

Both Ron and Audrey are extremely proud of the work Le Bac has accomplished over the years. “Some of the incredibly varied and innovative things we have done include creating a new process for manufacturing cylinder heads, engine blocks and other components for drag racing and tractor pulling; designing and building plastic cases and components for electronic enclosures used in a battery storage system by the U.S. Navy; becoming involved with OEMs by designing and taking financial responsibility for creating parts that replace purchased items, while saving enough money to justify a mold purchase; and helping young entrepreneurs bring their ‘start-up’ babies to market.

“When continuous true innovation is the key, doing it enthusiastically is of vital importance,” Ron adds. “I believe if we marry our engineering understanding of all the mechanical components created for each mold and fuse that with an enthusiasm for creativity and innovation, we can be successful in serving this customer today.”

For Ron and Audrey, the plan is for Le Bac to serve their customers for many tomorrows as well. “Universally, the people I meet who are in the workforce today say they believe they must work longer than was true in the past,” Ron comments. “The general consensus seems to be that there is no early retirement in sight for anyone ... workers or owners. My goal is to keep on keeping on. I take great pride in what we offer to our customers, and see Le Bac as a continuing creative resource in these uncertain times."

Audrey agrees. “It is hard to imagine Ron ever retiring,” she affirms. “He is currently actively working to keep cross- training our employees so that no matter what, there is always someone knowledgeable to answer questions and help customers—and bottom line—to get the job done.”

Related Content

Questions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreMMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More