Justifying a Mold Rebuild Using Collapsible Core Technology

Technical advantages prove there is ample reason to explore rebuilding—or retrofitting—traditional unscrewing tools.

Advancements in technology are most often the basis for revisiting a mold’s design and operation. Though rebuilding perfectly good molds goes against the normal objective of building them to last and run forever, tooling engineers and designers are widening their horizons to include options for not building the ‘same old same mold’.

For several reasons, collapsible cores have become a part of that widened horizon. Though available on the market for more than 35 years, they are to some new technology. For others, rack and gear unscrewing systems, for all their complexity and high maintenance, are still too embedded in the mindset for molding threaded parts. Despite this, collapsible core technology is seeing a resurgence of interest today.

Building a Case for Collapsible Cores

There are two types of collapsible cores on the market. One is the original spring/flexing steel type, which was first developed in 1968. Constructed of two main pieces, this collapsible core is made up of a one-piece, 12-segmented collapsible core body and a center pin. These cores are actuated by the mold ejector plates and provide complete collapse with every cycle.

The second type of collapsible core is more mechanical in nature and is called the dove tail collapsible core. It was developed and introduced to the market in 2009. Typically, this style has six segments and offers variable collapse, split plate actuation and simplified sequencing.

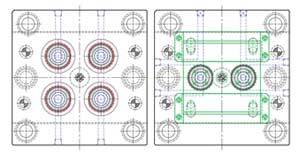

Collapsible cores take the complex actions away from the mold base and contain them within each core, making the mold build more straightforward. They also allow for a more balanced, square layout which results in a more balanced runner system. As a result, the collapsible core mold is easier to handle and can be installed in the press in one piece and in most cases can even utilize a smaller press.

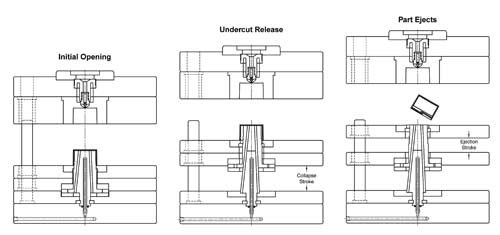

Collapsible core technology offers many sequencing options and if designed correctly, a mold may be run with only machine open & close. One can also sequence the mold using hydraulic cylinders for part ejection or the machine knock-out for core collapse and ejection.

From a maintenance standpoint, there are fewer components to deal with when using collapsible cores. Oil leaks have been all but eliminated because there are no gears or racks, there are fewer wear contact areas within the core itself (no spinning, no unscrewing, no bearings), and, unique to the dove tail style, maintenance techs can pull and service each individual core while it is in the press, clean it, and reinstall it, resulting in less overall downtime.

Better Part Quality, Faster Cycles

Collapsible cores often produce better quality parts compared to those molded using rack and gear systems. There are fewer rejects, more consistent parts and less contamination to deal with because there is minimal and, in some cases, no lubrication required.

Cycle time savings is a notable advantage with collapsible core usage. Since there are no racks and gears, there is no waiting for the molded part to unscrew from the core prior to ejection. This is especially beneficial if molding high pitch, high revolution caps. One can also eject a warmer part because the plastic does not have to set up as long to overcome the torque required to unscrew the cap from the core. In addition, one can start the collapse at mold open, allowing faster ejection. More parts per hour equates to a quicker return on one’s investment.

A real-world example of a mold rebuild project comes from Mold-Rite Plastics in New York—a manufacturer of rigid plastic caps, who designs and builds its own molds allowing them to offer complete design, engineering and printing

services for customers’ total and component packaging needs. Mold-Rite was running a 12-cavity buttress cap mold for more than 20 years. The tool had become a costly burden to maintain and inefficient to run. Mold-Rite was familiar with collapsible cores and when the dove tail core was introduced, the decision was made to rebuild the mold and incorporate the new style cores. Not only was the maintenance time and cost significantly reduced, Mold-Rite saw dramatic results on its production numbers:

Original mold: 12 cavity, 24.5-second cycle, 1,763 pcs/hr.

New dove tail core mold: 12 cavity, 14-second cycle, 3,085 pcs/hr.

In addition to a gain of 75 percent more parts per hour, Mold-Rite also reported a first year savings of $40,000.

Retrofit Option

Many times an older, high-production mold is still churning out needed parts, but has become tired and problematic, requiring costly downtime and maintenance, especially where worn cores are concerned. If the cavity half and hot runner

are still in good condition, the option is there to retrofit an entirely new core half to the original cavity half, giving new life to that old mold.

For example, one molder in Canada had an old and large 32-cavity unscrewing cap mold. Because of the size of the mold and the external hardware required for the unscrewing action, this mold had to be set into the machine in several pieces. The company decided to go with the retrofit option using collapsible cores. By eliminating the external unscrewing hardware in favor of the dove tail cores, this company reaped notable results:

- Ability to hang the mold into the machine in one piece, dramatically reducing set-up times.

- Reduced cycle time from 18.5 seconds down to 11 seconds—a 68 percent gain in mold production.

Summary

The technical advantages discussed here prove there is ample reason to explore rebuilding—or perhaps retrofitting—

traditional unscrewing tools. Regardless of which option is ultimately chosen to mold threaded parts—collapsible cores and unscrewing or jump-thread applications—doing the

math to ascertain the best overall return on investment can mean the difference between increasing one’s competitiveness and merely maintaining the status quo.

Read Next

Cost of Ownership: A Lifetime of Molding Savings

“There’s nothing more expensive than a cheap mold,” has been said by many a tooling engineer after a bargain of a mold began bleeding profits.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More