MMT Blog

Automation: Where to Begin And End

How mold manufacturers are benefitting from today’s automation options.

Read MoreValue of Retrofitting A Machine With a Robot

How a company can do more with existing equipment and manpower.

Read MoreThe Dielectric Decision: Water or Oil

The emergence of today’s technologically advanced oil-based wire EDMs is an opportunity for the average U.S. mold builder to set himself apart from the competition.

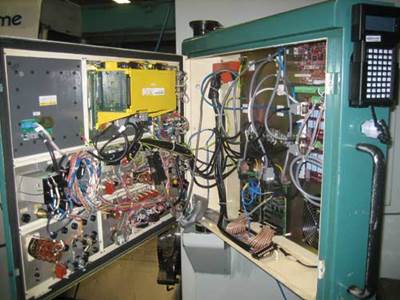

Read MoreFour Key Areas Of EDM Maintenance

Simply monitoring and maintaining four key areas on an ongoing basis will extend machine life and reduce long-term maintenance and service costs.

Read MoreDFMA Software: Opportunities in Disguise

Design for manufacture and assembly software enables better communication between manufacturers and design teams, so problem-solving relationships are developed and successful products are created.

Read MoreSacrificing Tool Life for Increased Productivity

To compete overseas by improving productivity, moldmakers need to focus on lowering the total machining cost per component.

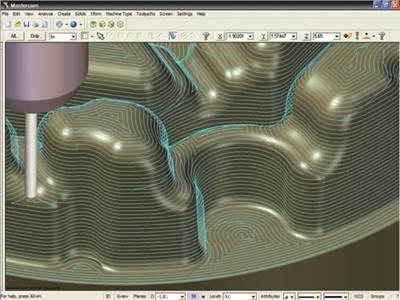

Read MoreThree Reasons to Maintain Your CAD/CAM

Maintain Your CAD/CAM Software, like any tool in the shop, needs maintenance.

Read MorePrecision Electrolytic Machining

Create tools with high tolerance, precision and a smooth surface finish with precision electrolytic machining.

Read MoreMeasuring the Effectiveness Of Your Mold Machining Ops

A review of the shortcomings and solutions to OEE challenges.

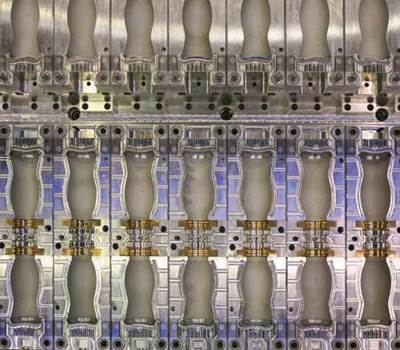

Read MoreUniloy North America: Total Systems Outlook

Uniloy North America has specialized in blow mold machine and mold manufacturing for more than five decades.

Read MoreCreating Constructive Change: Efficiency Applied

Simple, inexpensive changes helped Prodigy Mold and Too create an environment that changed the complexion of their business.

Read MoreStrategic Capital Purchases Help Tap into New Markets

How LS Mold, Inc.became an expert in rapid tooling..

Read More