MMT Blog

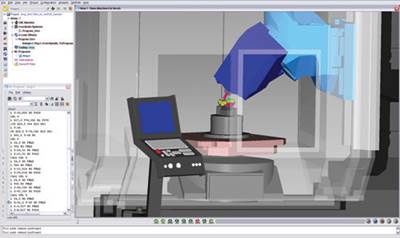

Simulation Software: A Virtual Methods Testing Lab for New Opportunities

NC verification and simulation software has been available to manufacturers for more than 20 years, yet most NC programmers do not take full advantage of the benefits it can offer.

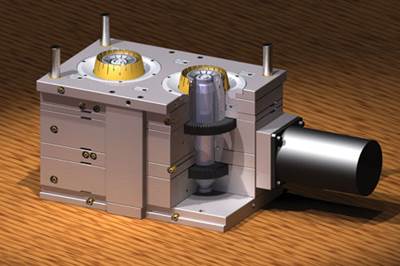

Read MoreMolder Only Runs One Mold with Fast Servo Motor— Instead of Two

About this series: For those charged with raising the sales of a mold building company, differentiating one’s company from the competition is fundamental. This quarterly series features actual examples of the front-line representative of a mold building company presenting new approaches to improve the customer’s profitability.

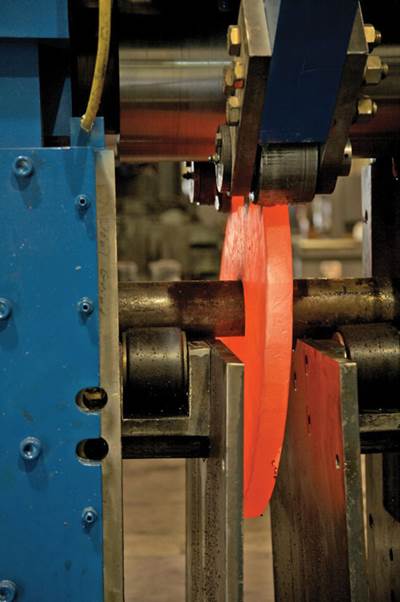

Read MoreElectric Valve Gates Deliver Higher Speed and Precision

For productivity increases, faster speeds and more control over material flow, this hot runner technology is worth a look for cleanroom applications.

Read MoreFour Facts about High-Performance Copper Alloys

Improve your global competitiveness by using high-performance copper in your molds.

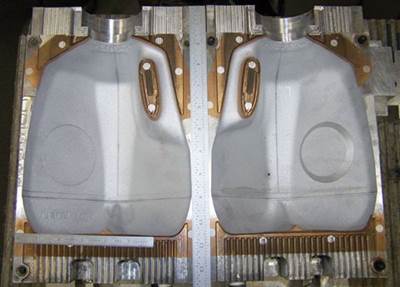

Read MoreWhat Is the ROI Of 3-D Scanning?

A moldmaker wanted to re-qualify used molds to see if they needed refurbishing, and if so, where to make the corrections.

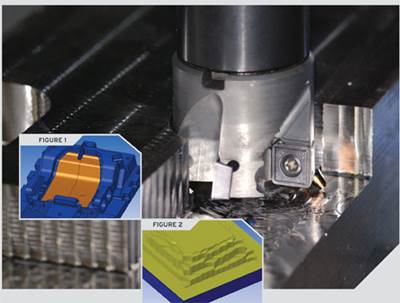

Read MorePractical Solutions To Common Machining Problems

Matching the roughing algorithm and tooling to the milling machine being used to machine the part is critical for high productivity.

Read MoreHow to Determine The Real Cost Of Your End Mill

More often than not, the first question a moldmaker asks when presented with an end mill is, “How much does this tool cost?” For this, there is really only one answer, “I can tell you the price, but I cannot tell you the cost until you run the tool.”A higher priced tool can ultimately prove to cost much less than its lower priced counterpart.

Read MoreAdding Molding Capabilities Strengthens Moldmaking

In a highly competitive market, offering your customers molding services in addition to mold manufacturing is a wise business decision to differentiate your company from the competition.

Read MoreSmall Shop HM CS Tool Engineering: The Business Of Customer Service

Despite its location in Cedar Springs, MI—a state that has been hard hit by the economic downturn—CS Tool Engineering, Inc. has landed the 2010 Leadtime Leader Award Small Shop Honorable Mention by constantly investing in technology and offering its customers complete customer service with leadtimes between 10 and 12 weeks.

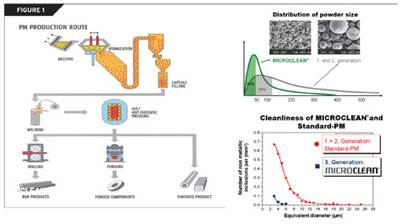

Read MoreNew Developments in P/M Steels for Moldmaking

Highly alloyed steels are difficult to manufacture using conventional steel melting methods.

Read More