Predictive Maintenance: How to Keep Machinery Running

The moldmaking industry can experience cost-saving benefits and crisis aversion with the right predictive maintenance program.

In this competitive market, companies are looking to predictive maintenance as a way to monitor their production machinery. By avoiding downtime and last-minute repairs, companies can save money and not miss a beat in the production cycle. Machinery used in mold manufacturing is very similar to machinery used in many other machining and production operations, and so the moldmaking industry is not an exception to the cost-saving benefits and crisis aversion provided by a predictive maintenance program.

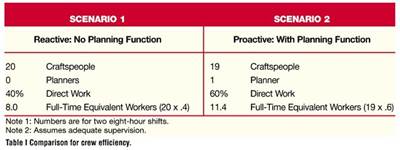

However, one aspect that differentiates mold manufacturers from other industries is that the moldmaking industry does not mirror the common metalworking production facilities producing multiple components of a high-volume nature using CNC machinery. Large production facilities have 50 to several hundred machines with precision rotating equipment, which economically supports the ROI of a full predictive maintenance program.

Many mold shops do not use near the volume of precision rotating equipment to justify a full-scale program, which can include the cost of analysis equipment, monitoring personnel and predictive consulting companies. Nonetheless, a machine down crisis can be just as damaging. In order for the moldmaking industry to benefit from the proven savings of a predictive maintenance program, a simpler, cost-effective solution must evolve.

Article continued below

A Cost-Effective Solution

A scalable predictive maintenance program1 precisely fits the needs of a mold manufacturer. Full-scale predictive maintenance programs require costly hardware and software, whereas a scalable one is easy and inexpensive to install, requires a low capital investment and the machinery can be monitored from anywhere.

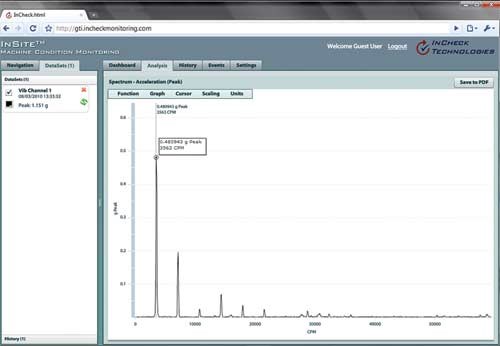

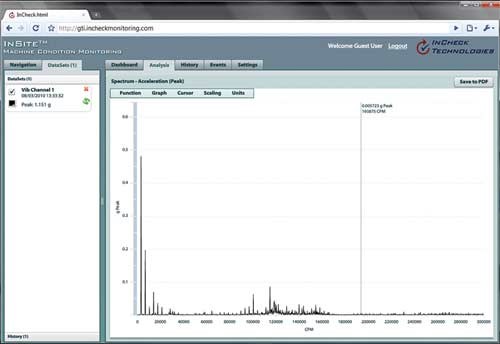

The right scalable predictive maintenance program includes a condition monitoring system that provides data collection, storage and processing facilities for condition and performance monitoring in a complete web-based solution. The system consists of sensors, wireless data acquisition modules and a software service component. Once installed, the data acquisition modules automatically connect to the program’s application server and start collecting and sending data from the sensors to the server. The system uses standard network infrastructure—such as local and wide area networks and the Internet to communicate, which saves even more money as these systems usually already exist at the plant.

The server processes data and stores it in an integrated database, giving users access to historical data. To monitor machines, users log in to the server and use the software service component to monitor and analyze the data, which can be done through a standard web browser. This software does not have to be purchased and is instead provided as a service. The software service component lets users perform vibration analysis, compare history and current data, and analyze trends for multiple parameters. The system also automatically notifies users by sending alerts through e-mail or text messages.

This is an alternative to the common practice of having a consultant travel to a site, collect data, and then analyze and report the data to make important decisions. Instead—with a scalable predictive maintenance program—a third-party consultant can view data through the Internet instantly, as can any internal specialist. Since it is a 24/7 online monitoring system, measurements do not have to be taken manually, trending of data becomes more accurate and one analyst can now evaluate data from multiple facilities from any site with an Internet connection.

Summary

With this technology, a mold manufacturer can now choose to monitor a few critical machines that would bottleneck or disable production at an affordable price, and have an option of adding other machines to the program. Knowing when a machine downtime could occur allows for the implementation of a proactive plan that would not interrupt production.

The moldmaking industry is no less under pressure to meet customer deliveries than the largest production companies, and with a solution a scalable predictive maintenance program, mold manufacturers and other specialty industries have the opportunity to use predictive maintenance technology to save money and avoid downtime.

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreHow to Correctly Size a Hydraulic Cylinder

This week Randy shares steps for correctly sizing a hydraulic cylinder on a mold.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRead Next

Managing Maintenance Improvement Initiatives

The recent revision of ISO 9001 has again changed the standards landscape, placing the burden on manufacturers to define and measure their internal processes. Many are looking for a practical approach that gets the job done right the first time.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More