Four Facts about High-Performance Copper Alloys

Improve your global competitiveness by using high-performance copper in your molds.

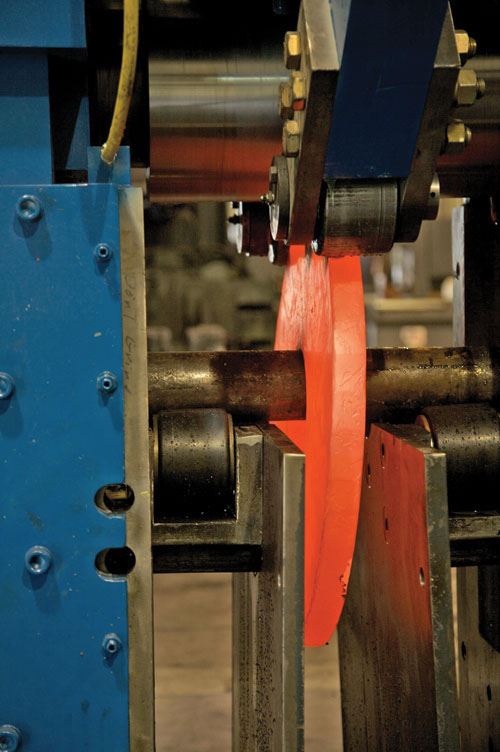

In order to be ultra-competitive in this difficult economy, another arrow in the quiver of toolmakers is high-performance copper, which can be employed instead of traditional all-steel tools. The use of high performance copper alloys in mold cores and cavities gives significant advantages over tool steels and aluminum alloys. It has been proven that high-performance copper alloys are capable of producing significant part cost reductions and dimensional tolerance improvements via their excellent thermal characteristics, while maintaining strength and hardness to meet the demanding requirements of injection molds.

Due to the fact that copper alloys are more expensive than typical mold steel, moldmakers are often hesitant to use these alloys. There are two primary reasons why copper beryllium alloy C17200 and other high performance copper alloys are used in molds which we will discuss: (1) cycle time reduction and capital savings and (2) part quality. This article will also review key mold material properties and the compatibility of glass-filled polymers.

1. Cycle Time and Capital Savings

For molders whose machines are running at 50-percent capacity—which is not so uncommon in this difficult economy—cycle time reduction is not at the top of their priority list. However, there are times when making a mold with fewer cavities—or making one mold instead of two—is made possible by using high-performance copper alloys. There are many examples where the use of copper has allowed molders to produce on four cavities what otherwise would have required an 8-cavity mold. Imagine if you can use one mold instead of two—eliminating the need for an extra molding machine. Now we’re talking about hundreds of thousands of dollars in savings for perhaps a few thousand dollars extra in mold materials.

Often, molds are built with the least expensive steels because there is a disconnect between the moldmaker, the mold owner and the molder. For example, if a major OEM buys a mold, but the mold is run by a subcontractor, there needs to be very good discussion regarding the price of the mold, the cycle time of the parts and the quality of the parts. If the OEM purchases the tool he may want the cheapest tool possible. The molder then must convince the OEM to spend a little extra in order that the mold will meet the cycle time and part quality requirements, and finally the lowest total cost for the molded parts.

2. Part Quality

Besides decreasing cycle time, the high thermal conductivity of copper alloys also increases the thermal homogeneity of the part during cooling, which in turn reduces warping. If a tool has poor thermal conductivity, then hot spots can develop during the cooling process. Hot spots are regions where the tooling temperature is higher than the surrounding material and the local cooling rate of the molded part will be lower than that of the rest of the part. This variability in cooling rate can lead to parts warping, yielding inferior and sometimes unusable products.

There are many examples where a mold is built entirely in steel and the part dimensions and shape are impossible to keep within tolerance. Then, as an afterthought, copper alloys are inserted to solve the problem. Inserting copper after the fact solves the problem, but it is much more cost-effective to design copper into the mold from the very beginning.

3. Key Mold Material Properties

There are other crucial material properties to consider: strength and hardness. A hard material reduces wear, improving longevity as it reduces the susceptibility of the mold to dents and scratches. However, the material cannot be brittle, so the alloy needs to have both strength and hardness. Therefore, an ideal material for a cavity or core is one that optimizes strength, hardness and conductivity. Aluminum and lower performance copper alloys have high conductivity, but inadequate hardness and strength for many tooling applications.

There is vast evidence to support that copper beryllium C172 is really the best high-performance copper alloy for molds. No other material is available in the 40 HRc range with thermal conductivity close to CuBe C17200. Other materials have been developed such as CuNiSiCr that are also very good alloys with a maximum hardness of 30 HRc. The size ranges of the CuNiSiCr alloys in the 30 HRc range are very limited—typically up to 5” maximum thickness. Thicker plates are available, but with lower hardness. In addition to thermal conductivity, it is important to also consider material properties such as corrosion resistance, machinability and weldability.

4. Compatibility with Glass-filled Polymers

Suggest that someone use a copper alloy in a mold for glass-filled polymers and many people will immediately reject the idea. However, glass-filled polymers are molded every day in tools on every continent using C17200 with a hardness of 40Rc. We must remember that in most instances, the polymer is not flowing along the wall of the mold, but is flowing with a fountain flow inside-out pattern—meaning that the velocity of the polymer at the mold surface is zero. We do have to be careful though, in gate areas and where there are sharp corners with thin walls. The mold life can still be very good, but there may be circumstances where weld repair is required or replaceable inserts are recommended.

Summary

Material selection for mold tooling is never easy and requires the balancing of a number of competing factors. It is apparent though, that particularly when dealing with large volume or high precision production runs, dramatic savings can be achieved by employing high-performance copper alloys as opposed to steels such as P-20, H- 13 and 420 or aluminum alloys.

The C17200 alloy requires a higher initial investment, but this cost can very quickly be recuperated by the significant savings associated with the dramatically reduced cycle times and part deformation. Furthermore, hybrid molds of steel and C17200 alloys are typically the best tools produced, giving the price advantage of steel, while still reducing the incidence of warped, unusable parts.

Related Content

Cast Plate Aluminum Alloy is Suitable for Production Mold and Dies

Alimex Precision in Aluminum introduces its 7000 series ACP7 mold material, featuring high mechanical properties, material stability and good machinability.

Read MoreHow to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection, there are many variables that can dictate the best option for moldmaking.

Read MoreSolid Carbide Cutter Mills Aluminum

Roughing and finishing deep pockets and cavities are the primary feature strengths behind this Walter MC166 Advance cutting tool.

Read MoreAluminum Plate for High-Temperature Tooling Applications

NPE2024: Ellwood Specialty Metals exhibits its EllCast 2 aluminium plate. Its strength at high temperatures, combined with high thermal fatigue resistance and hardness, makes EllCast 2 ideal for critical applications.

Read MoreRead Next

Twenty Years of Copper Alloys in Moldmaking

A look at where we are today with the integration of copper alloys in mold building.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More