MMT Blog

Capitalizing on a Packaging Niche

Top Grade Molds Ltd. (TGM; Mississauga, ON) has always been known for its thin-wall, open top molds for the industrial packaging market.

Read MoreWhat Buyers Want May Not Be What They Want

Rather than asking “What Do Buyers Want?” it makes more sense to target the “pain points” that buyers in manufacturing and industrial markets are feeling these days and model your messaging and tactics to define your business as “pain relief.”

Read MoreGetting Up to Spec

Steps to follow for discovering needed information about inherited tooling.

Read MoreTooling Design for Silicone Molding

One of the biggest challenges in mold design for silicone molding is the runnerless molding system or cold deck.

Read MoreChoose the Right Cutting Tool Strategy to Machine Efficiently and Affordably

A look at a couple current cutting tool technology trends: aluminum machining: face milling and mold steel machining: high-feed milling.

Read MoreSustained Commitment to Automation Reaps Rewards

Through consistent automation strategies, one mold shop was able to implement new equipment and ramp up training, allowing them to accelerate out of tough times and be prepared for upcoming business opportunities.

Read MoreFour Key Uses of Prototyping

Prototyping helps evaluate and test a design, clarify production costs, sell a product and secure patents.

Read MoreManaging Bankruptcy Through the Eyes of the OEM, Molder and Moldmaker

Obtaining accurate information of closely-held companies and corporations is difficult.

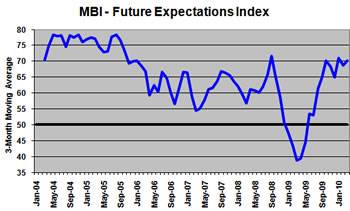

Read MoreRising Corporate Profits Bode Well for Moldmakers

If you ask any red-blooded, patriotic American manufacturer what he or she is in business to make, the answer should be quick and simple.

Read More